Performance+ OKU Panel Solar Pool Heating System -- Installation and User Manual

These online install instructions are also available in printable pdf form; download here - Performance+ OKU Panel Solar Pool Heating System -- Installation and User Manual.

Tip: If you need to email us a question about a specific section of this manual, you can use the headings "Get Link" button to copy a hyperlink which will automatically jump to that section when loaded on a browser.

EcoOnline Performance+™ Solar Pool Heating System -- Installation & User Manual

© Copyright 2021 Optex Solar Pty Ltd. All rights strictly reserved.

EcoOnline™ Performance+

OKU Panel Solar Pool Heating System

Installation and User Manual - Revised 19/11/2021

Optex Solar Pty. Ltd.

ABN: 88 128 228 884

www.EcoOnline.com.au

email: info@EcoOnline.com.au

© Copyright 2021 Optex Solar Pty Ltd. All rights strictly reserved. This publication is protected by copyright law

and unless otherwise specified is for your personal and non-commercial use only. No part of this publication

may be reproduced or distributed by any process, electronic or otherwise, without the specific written

permission of Optex Solar Pty Ltd. Trademarks appearing in this manual are the sole property of Optex Solar

Pty Ltd or their respective owners. Nothing in this publication shall be construed as granting any express or

implied license to use any intellectual property of Optex Solar Pty Ltd otherwise than for personal and

non-commercial use only. Optex Solar Pty Ltd must not, to the full extent permitted by law, be held liable

for any claim, cost (including legal costs), damage, expense, loss (including fines, penalties, set-offs and

consequential loss) or liability arising from the use (or misuse) of any product described in this

publication, unless expressly provided otherwise in this publication. Information as well as any

products described in this publication are subject to change without notice.

EcoOnline Performance+™ Solar Pool Heating System -- Installation & User Manual

© Copyright 2021 Optex Solar Pty Ltd. All rights strictly reserved.

Page 2

Contents Click Heading Titles to Navigate Up or Down

14.1 Ladder Safety

EcoOnline Performance+™ Solar Pool Heating System -- Installation & User Manual

© Copyright 2021 Optex Solar Pty Ltd. All rights strictly reserved.

Page 3

EcoOnline Performance+™ Solar Pool Heating System -- Installation & User Manual

© Copyright 2021 Optex Solar Pty Ltd. All rights strictly reserved.

Page 4

26.1 Drain Down

26.2 Winterization

30.1 Notes on First Usage

EcoOnline Performance+™ Solar Pool Heating System -- Installation & User Manual

© Copyright 2021 Optex Solar Pty Ltd. All rights strictly reserved.

Page 5

1 Key Terms

Create jump link to this section-- Get Link

This manual was written to follow guidelines and recommendations given in:

AS 3634 - 1989 Solar heating systems for swimming pools

AS 1170.2 - 2011 (Amend 2 Dec 2012) Structural design actions - Wind actions

‘HAZPAK’ produced by the work-cover authority

AS 3000 (2007) Sections 6.3, 6.4 & 6.5

AS 1926.1 & 1926.2 (2007) swimming pool safety - location of safety barrier

Please take the time to read this manual before starting any work. Particular attention should be given to text

contained in the following key terms.

Please note EcoOnline has a strong product safety policy; do not install products without reading safety guidelines in

the manual. Please report any product safety issues or near misses to info@EcoOnline.com.au no matter how trivial.

Refers to useful information for the optimal operation of the system

Indicates a SAFETY issue that is likely to cause injury or death if the user does not

follow the instructions.

Indicates a SAFETY issue that may cause injury or death if the user does not follow the

instructions.

Indicates a SAFETY issue that may cause injury or property damage if the user does

not follow the instructions

Refers to critically important information related to the correct functioning of the

system.

Why? Italic text is optional reading. Gives extra information and reasoning for recommendations that are

non-obvious and/or counter intuitive.

EcoOnline Performance+™ Solar Pool Heating System -- Installation & User Manual

© Copyright 2021 Optex Solar Pty Ltd. All rights strictly reserved.

Page 6

2 Pre-Installation Suitability and Safety Checklist

Create jump link to this section-- Get Link

The following outlines mandatory suitability and safety requirements for installing this solar heating system. Please

read carefully, if any of the following requirements cannot be meet the system should NOT be purchased or

installed.

For ground level collector installations the installer MUST check child safety fence regulations

in the relevant state. Under no circumstances should collectors be installed so as to

compromise the effectiveness of a child pool or spa fence safety barrier by providing a

climbable object.

Building regulations vary from state to state and MUST override any instructions supplied in

this manual. It is the responsibility of the purchaser/installer to check that installations

comply with any relevant state laws and regulations.

At present this collector array system is not recommended for exposed installations in

cyclonic regions C or D, or on houses situated on top of hills in cyclonic region B, or on

second story (or higher) roofs. Installations on tiles are for Wind Region A only.

Collectors are to be used with chlorinated (or otherwise sanitized) pool water ONLY. Do not

use collectors to heat fresh (untreated) water due to the potential for Legionaries bacteria

build up.

This appliance is not intended for use by persons (including children) with reduced physical,

sensory or mental capabilities, or lack of experience and knowledge, unless they have been

given supervision or instruction concerning use of the appliance by a person responsible for

their safety. Children should be supervised to ensure that they do not play with the appliance.

Due to the potential of falling from heights, mounting panels on a roof or structure at

heights should only be undertaken by a professional installer, unless you are accustomed

to and confident of performing the work safely. We strongly recommend the installer

invests in roof safety guard rails and a safety harness system, especially for DIY

applications.

EcoOnline Performance+™ Solar Pool Heating System -- Installation & User Manual

© Copyright 2021 Optex Solar Pty Ltd. All rights strictly reserved.

Page 7

3 Warranties

Create jump link to this section-- Get Link

EcoOnline™ offers the following Warranties

35 year limited Warranty on all OKU collectors

2 year Warranty on Davey Pool Pumps

3 Year Warranty on Dontek and Ascon Controllers

See our Terms and Conditions page for further details: www.EcoOnline.com.au/terms-and-conditions

4 System Sizing Guarantee

Create jump link to this section-- Get Link

Sizing systems is difficult involving a lot of factors which we could get wrong. Hence in addition to the above

Warranties EcoOnline offers a System Sizing Guarantee as follows. If we sized your system (or you use our online

calculator) and you took our advice and you aren’t happy with the system’s performance (heat output), then you can

purchase up to 25% more panels originally supplied by EcoOnline up to two years after your original purchase and

we will ship the items free of shipping charges.

5 Collector Sizing Guide

Create jump link to this section-- Get Link

An interactive collector sizing calculator and pool water temperature simulator can be found on our website at:

www.EcoOnline.com.au/pool-heating-sizing-calculator

www.EcoOnline.com.au/pool-water-temperature-simulator

5.1 A Word on Transparent Bubble Pool Covers

Create jump link to this section-- Get Link

EcoOnline recently carried out a full pool heating loading technical study including performance data on transparent

bubble pool covers. We found that while transparent pool covers produce a moderate heating effect by themselves,

they produced a much larger pool temperature boost when used in conjunction with a solar pool heater due to

synergistic effects. So much so that if you’re running a solar pool heater and not using a pool cover you are missing

out on surprisingly large temperature gains - see link below for the summaries:

www.EcoOnline.com.au/how-warm-can-a-pool-get-with-a-solar-heater-and-cover

Customer please note: WARRANTY IS VOID if collectors are installed:

without a vacuum release valve on the return line,

or a non-return valve on the solar pump outlet (with 6mm drain hole in flap),

or if panels are run at pressures other than a maximum of ± 1psi (6kPa),

or if the collectors are installed well below the water level (max 1.5m).

Why? Such installations will expose the collectors to strong fatiguing positive/negative

pressures. These situations will have detrimental effects on the collectors which will limit

lifetimes and can also result in significant shrinkage of the collectors which would put

strain on roof attachments.

EcoOnline Performance+™ Solar Pool Heating System -- Installation & User Manual

© Copyright 2021 Optex Solar Pty Ltd. All rights strictly reserved.

Page 8

So if you’ve used a pool cover before and had disappointing results, we highly recommend you try using a cover

again after you install our solar pool heating system.

6 Pool Chemistry Compatibility Guide

Create jump link to this section-- Get Link

7 Pump Sizing Guide

Create jump link to this section-- Get Link

7.1 A Word on Pump Sizing Choice

Create jump link to this section-- Get Link

The quick reference tables below outline Australian Standard pump sizing recommendations.

There is a range of pump powers one can choose from. If thermal system efficiency is important then choose a pump

at the high end to produce a high flow rate; take care not to over-pressurize your system (see Optimizing Collector

Pressure below). If electrical efficiency (COP factor) is important to you then choose a pump near the lowest power

range. To help you understand the potential savings from such choices we have created an interactive pump sizing

simulator which can be found on our website at:

www.EcoOnline.com.au/oku-performance-pool-heating-pump-sizing

However, if you go with a lower power pump you’ll need the following:

A slightly larger collector area; the pump sizing calculator will let you know by how much.

You will need to check with the pump manufacture that your chosen pump can still prime reliably at your

pump height.

We highly recommend you use a by-pass line to help your pump prime reliably, see Installing a By-Pass Tube

or By-Pass Ball Valve section below.

Please note the silicon joiners used in the system are not compatible with acidic pool/spa

water (pH less than 7.2). Sodium Carbonate must be added to protect the system from acidic

pH (<7). pH should be maintained between 7.2-7.8 for maximum longevity. If required Sodium

Bisulphate acid can be used to keep the pH down.

Why? Acidic water with pH less than 7.0 has excess free H+ ions which like to bond to and

hence break apart silicon bonds.

Only highly transparent clear and light blue solar blankets increase water

temperatures; silver backed or non-transparent solar blankets reject sunlight and will

substantially cool your pool - this is irrespective of whether or not the silver side faces

up or down. Non-transparent blankets are okay to use for 100% shaded pools only.

Variable speed or PV solar powered pool pumps are not to be used with OKU panels.

Why? Such pumps have large start up currents and will expose panels to high fatigue

working pressure fluctuations.

EcoOnline Performance+™ Solar Pool Heating System -- Installation & User Manual

© Copyright 2021 Optex Solar Pty Ltd. All rights strictly reserved.

Page 9

Lastly you may need to run your main filter pump in the afternoon to help mix the warm water if your pool

volume turnover falls below the 50% - 75% range.

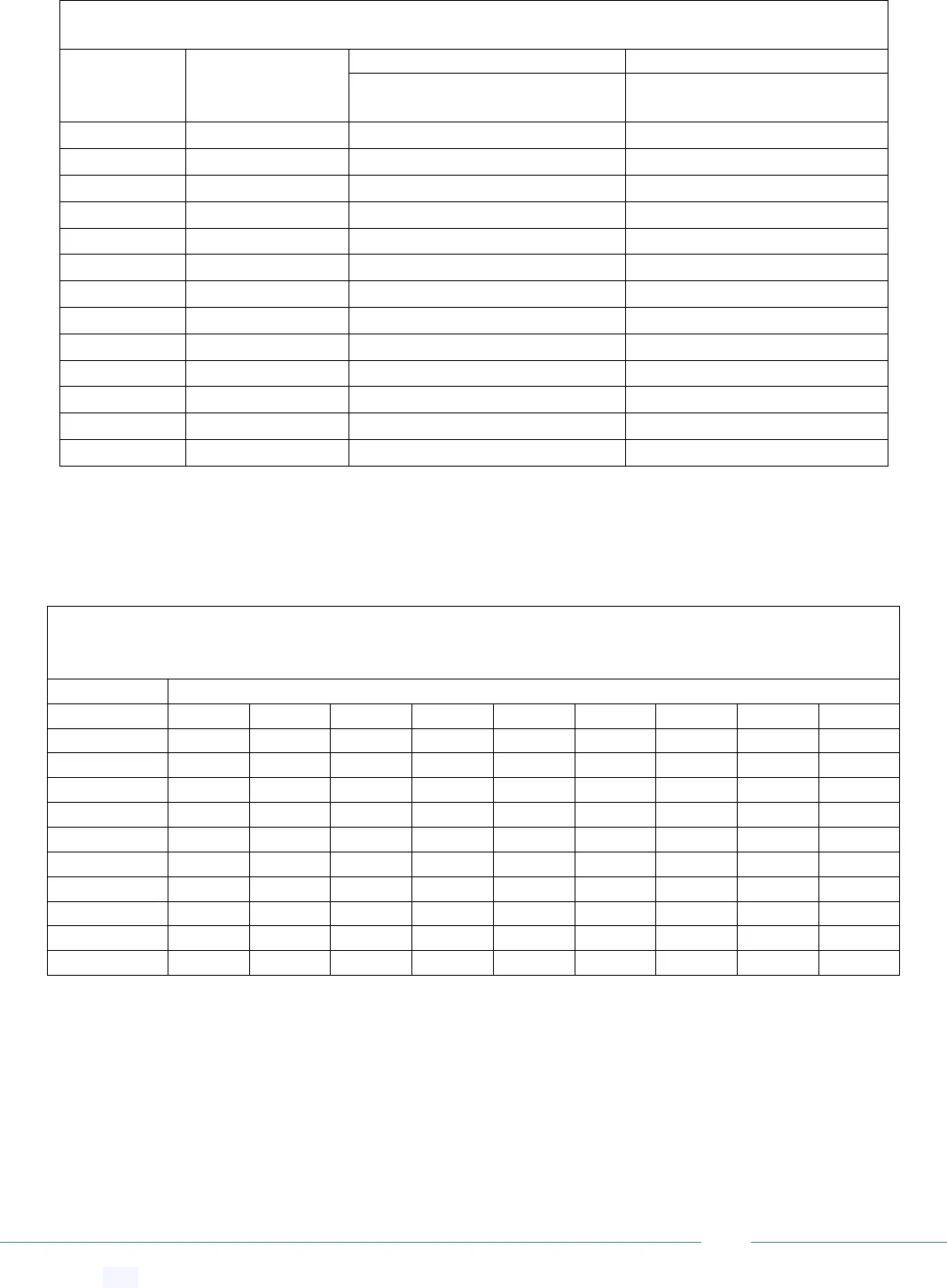

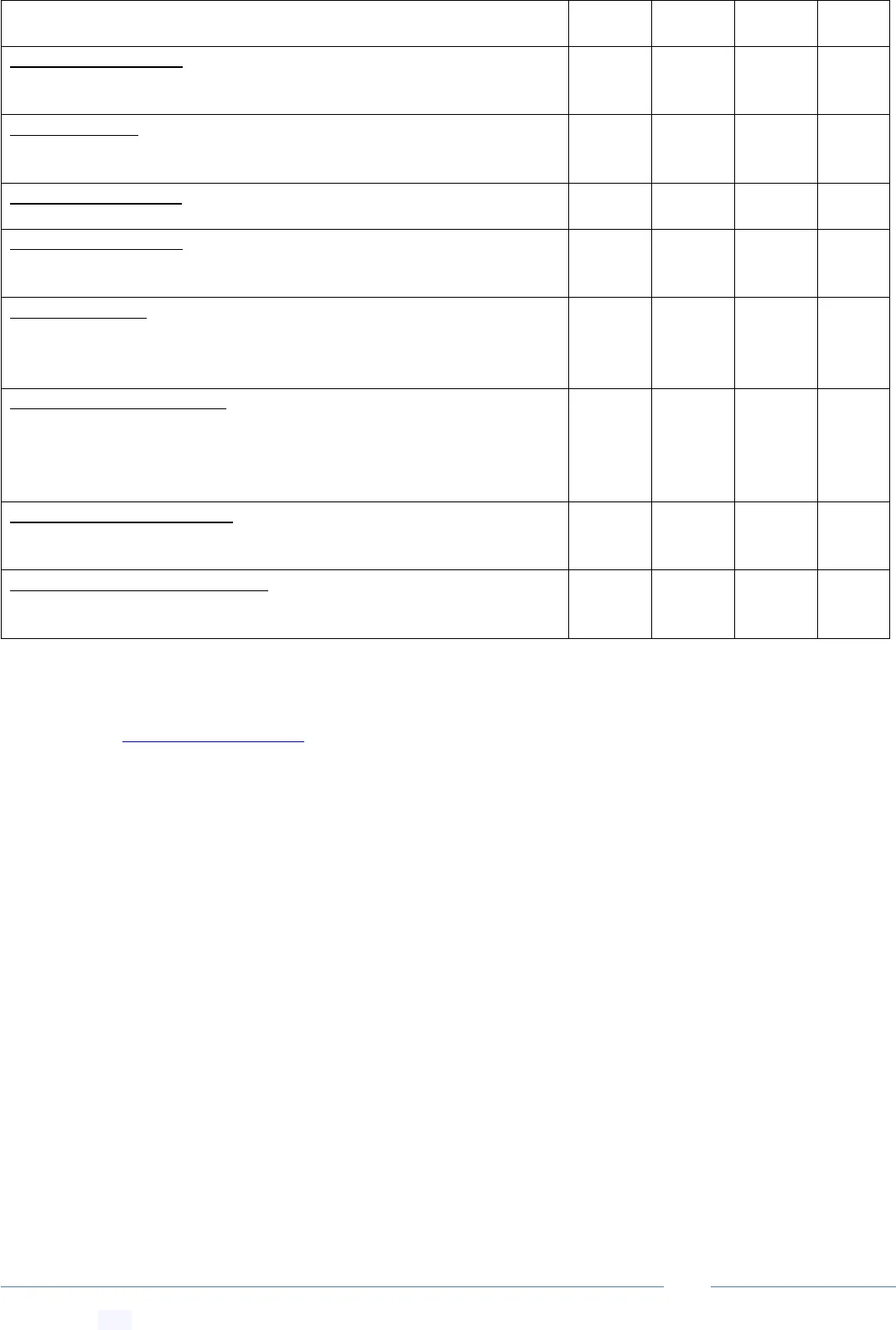

Australian Standard Input Pump Power for Independent Systems

For 1

st

Story Install (3m):

For 2

nd

Story Install (6m):

Pool

Water

Volume

Min - Max

Recommended

Flow

Min - Max

Input Pump Watts

Min - Max

Input Pump Watts

20,000 L

50 - 67 L/min

270 - 300 Watts

350 - 380 Watts

25,000 L

63 - 83 L/min

300 - 330 Watts

370 - 410 Watts

30,000 L

75 - 100 L/min

320 - 370 Watts

400 - 450 Watts

35,000 L

88 - 117 L/min

340 - 400 Watts

420 - 480 Watts

40,000 L

100 - 133 L/min

360 - 440 Watts

450 - 520 Watts

45,000 L

113 - 150 L/min

390 - 470 Watts

470 - 560 Watts

50,000 L

125 - 167 L/min

420 - 510 Watts

500 - 600 Watts

55,000 L

138 - 183 L/min

450 - 560 Watts

530 - 640 Watts

60,000 L

150 - 200 L/min

470 - 600 Watts

560 - 690 Watts

65,000 L

163 - 217 L/min

500 - 640 Watts

600 - 740 Watts

70,000 L

175 - 233 L/min

530 - 700 Watts

620 - 790 Watts

75,000 L

188 - 250 L/min

570 - 740 Watts

660 - 840 Watts

80,000 L

200 - 267 L/min

600 - 790 Watts

700 - 900 Watts

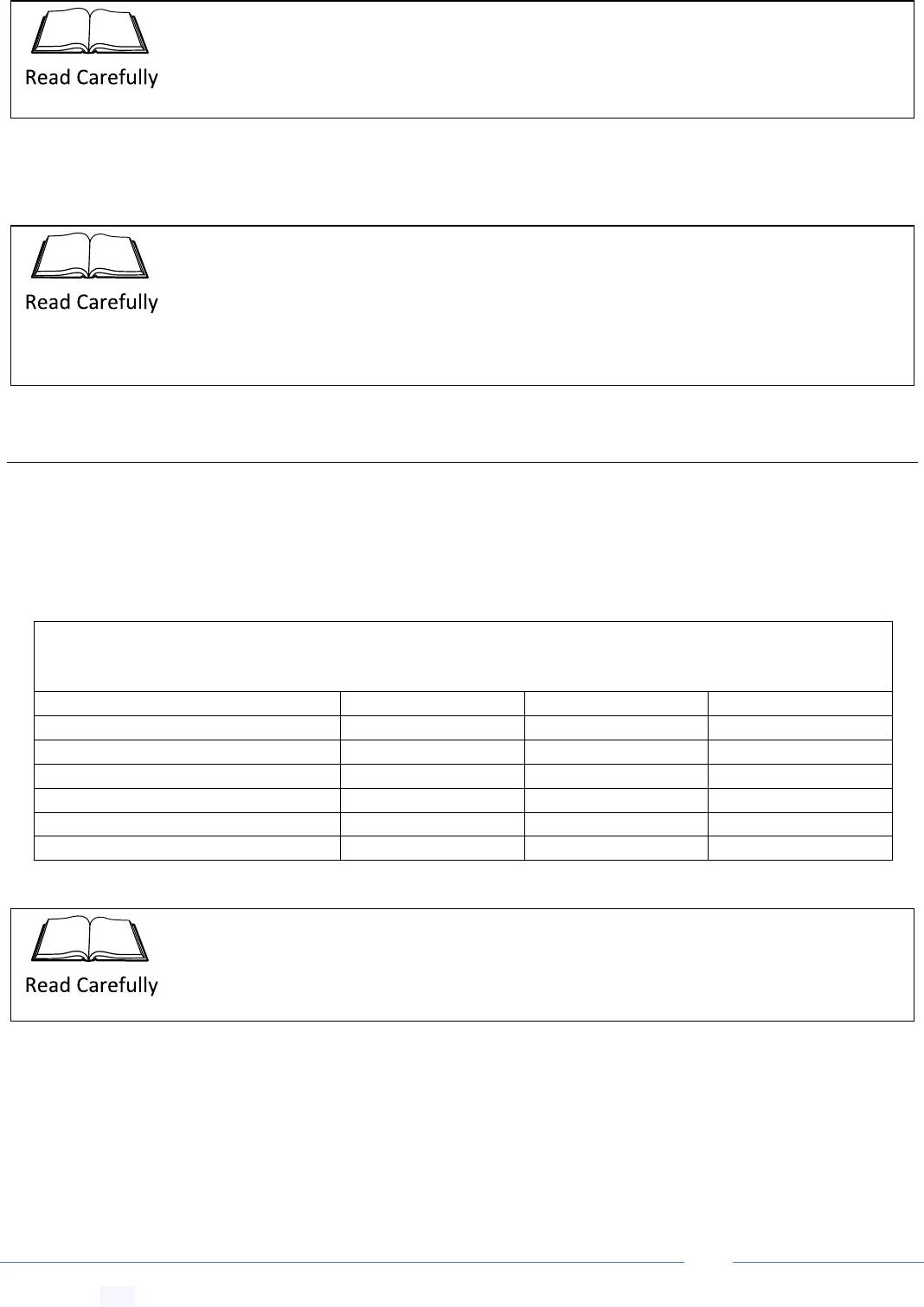

If you don’t know your pools water volume you can look it up from the table supplied below based on the total

water area and average depth:

Pool Water area vs Average Depth Conversion Table

Average depth

Waters Area

1.3 m

1.4 m

1.45 m

1.5 m

1.55 m

1.6 m

1.65 m

1.7 m

1.8 m

10 m

2

13000 L

14000 L

14500 L

15000 L

15500 L

16000 L

16500 L

17000 L

18000 L

15 m

2

19500 L

21000 L

21750 L

22500 L

23250 L

24000 L

24750 L

25500 L

27000 L

20 m

2

26000 L

28000 L

29000 L

30000 L

31000 L

32000 L

33000 L

34000 L

36000 L

25 m

2

32500 L

35000 L

36250 L

37500 L

38750 L

40000 L

41250 L

42500 L

45000L

30 m

2

39000 L

42000 L

43500 L

45000 L

46500 L

48000 L

49500 L

51000 L

54000 L

35 m

2

45500 L

49000 L

50750 L

52500 L

54250 L

56000 L

57750 L

59500 L

63000 L

40 m

2

52000 L

56000 L

58000 L

60000 L

62000 L

64000 L

66000 L

68000 L

72000 L

45 m

2

58500 L

63000 L

65250 L

67500 L

69750 L

72000 L

74250 L

76500 L

81000 L

50 m

2

65000 L

70000 L

72500 L

75000 L

77500 L

80000 L

82500 L

85000 L

90000 L

55 m

2

71500 L

77000 L

79750 L

82500 L

85250 L

88000 L

90750 L

93500 L

99000 L

EcoOnline Performance+™ Solar Pool Heating System -- Installation & User Manual

© Copyright 2021 Optex Solar Pty Ltd. All rights strictly reserved.

Page 10

7.2 Solar Pump Sizing for Booster Systems

Create jump link to this section-- Get Link

7.3 Filter Pump Sizing for Manual Systems

Create jump link to this section-- Get Link

8 Solar Line PVC Pipe Sizing Guide

Create jump link to this section-- Get Link

The table below will help you choose the correct size PVC pipe for the solar lines running to and from your roof. On

the roof, we generally recommend 32 PVC (DN30), except for larger multiple row arrays with a secondary header

pipe feeding each row, for which you should use 40 PVC (DN40). Coming down the roof the pipe size can then be

adapted to the pipe size you have for your solar line ground run i.e. 40 PVC (DN40) or 50 PVC (DN50).

Recommended PVC Piping Sizing for Solar Pool Heating System Lines

Anticipated Flow Rate

Absolute Minimum

Ideal PVC Pipe Size

Maximum Pipe Size

70 Litres/min

20 PVC (DN20)

25 PVC (DN25)

32 PVC (DN30)

120 Litres/min

25 PVC (DN25)

32 PVC (DN30)

40 PVC (DN40)

200 Litres/min

32 PVC (DN30)

40 PVC (DN40)

50 PVC (DN50)

250 Litres/min

40 PVC (DN40)

50 PVC (DN50)

65 PVC (DN65)

400 Litres/min

50 PVC (DN50)

65 PVC (DN65)

80 PVC (DN80)

880 Litres/min

80 PVC (DN80)

100 PVC (DN100)

125 PVC (DN125)

For booster type systems you should choose a pump at or just below the minimum

specs in the table above. Why? The take off point for solar is already pressurized by the

filter pump, hence a smaller pump should be used.

For manual type systems running off the main pool filter pump, please check that the

filter pump is large enough to accommodate the extra load of supplying water to the

collectors at the required pump height + a 1 meter pressure drop across the collector

array. Why? Filter pumps are geared for flow not pump height, solar pumps are geared

specifically for roof solar applications.

If the distance from the pool to the roof collector area is more than 10m we recommend

you use the next size up PVC pipe.

EcoOnline Performance+™ Solar Pool Heating System -- Installation & User Manual

© Copyright 2021 Optex Solar Pty Ltd. All rights strictly reserved.

Page 11

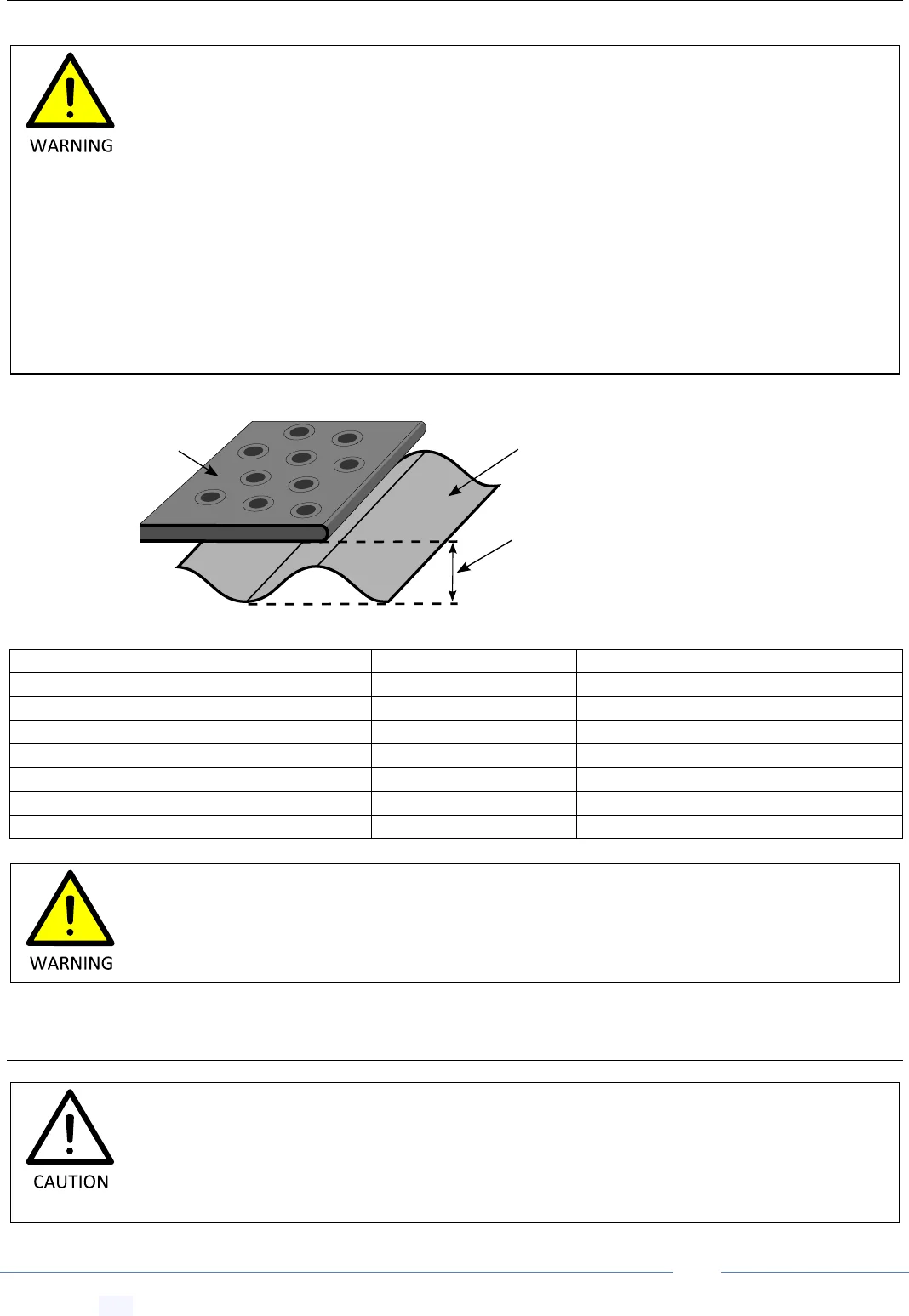

9 Roof Type Compatibility Guide

Create jump link to this section-- Get Link

Roof Type

Peak to Valley Measure

Recommendations

Standard Corrugated Iron roof (Custom Orb)

17mm

Use Respective Wind Region Fixings

Relatively Flat Tile roof

Less than 25mm

Use Respective Wind Region Fixings

Spandek Iron roof

24mm

Use Respective Wind Region Fixings

Modulated Tile roof

Greater than 25mm

Use Next Level Wind Region Fixings

Trimdek Iron roof

29mm

Use Next Level Wind Region Fixings

Klip-lok Iron roof

43mm

Use Highest Wind Region C Fixings

Flatdek Iron roof

45mm

Use Highest Wind Region C Fixings

10 Wind and Climate Considerations

Create jump link to this section-- Get Link

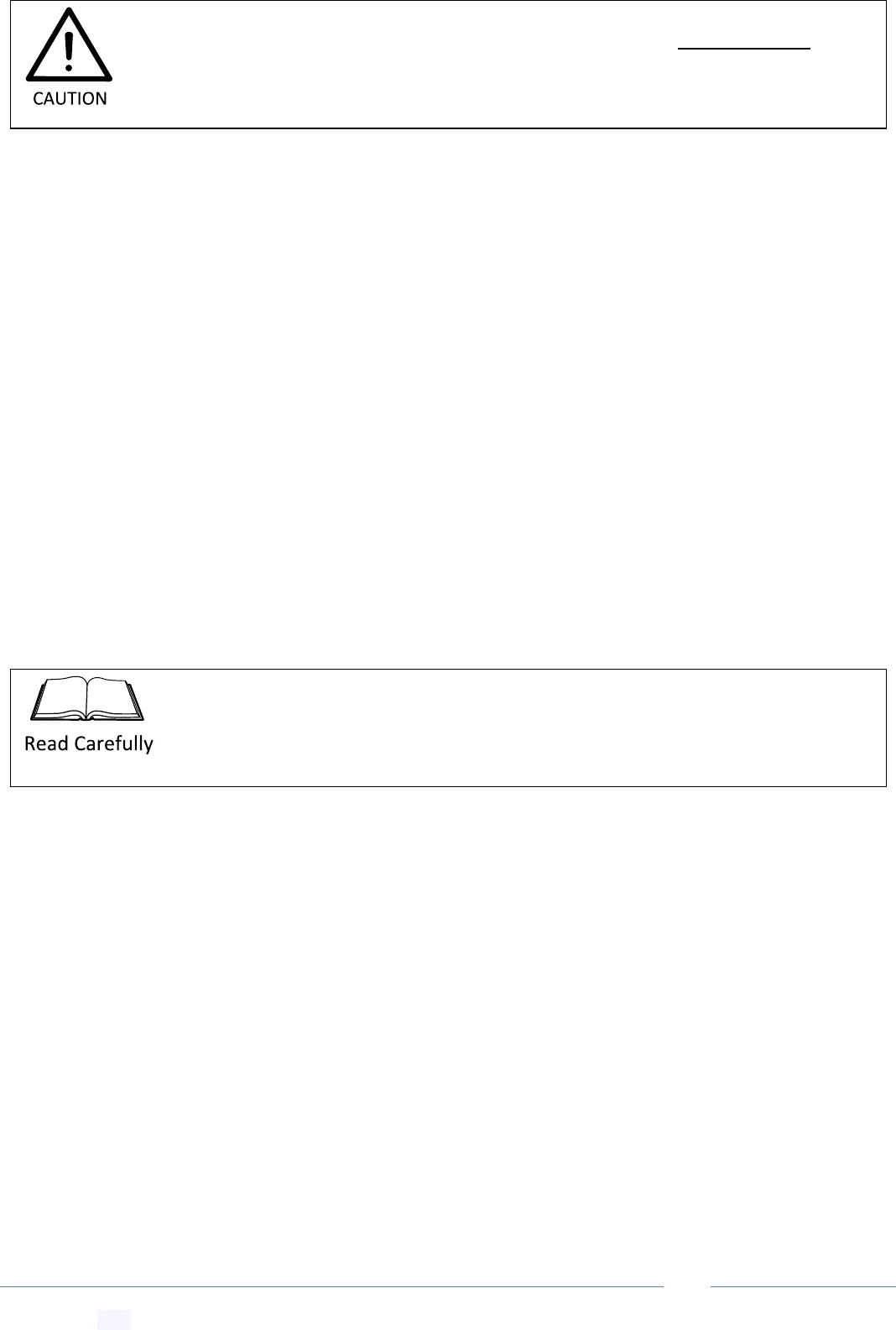

Collector bottom to roof valley air

gap should perferably be less than ~ 45mm

(for gaps > 45mm - use Wind Region C fixings)

Corregated metal roof

or tile roof

Collector Panel

If panels are to be installed on a roof then the following should be observed to limit wind

uplift potential.

1) Installed panels should lay flat close to the roofs surface. It is recommend the air

gap distance between the bottom of the installed collector and the valley points of

the roof corrugations should be no greater than approximately 40mm.

2) Panels should have adequate clearance from roof edges.

3) Panels on roofs MUST NOT be mounted on tilt frames.

Why? The average air gap distance between the mounted collector and roof structure has a

strong influence on wind loadings. Furthermore due to roof edge turbulence effects wind

loadings are highest near roof edges.

Panels installed above the roof structure with 50mm or greater underneath air gaps experience

much higher wind loadings and are now subject to the Australian wind loading standard

AS/NZD 1170.2.

It is the responsibility of the installer to consider wind loading factors, see “wind proofing”

section below. If the installation site is within strong wind speed areas then the extra

stainless steel guide line must be installed across each row with the in-between panel

anchor points. Do not assume supplied components are sufficient.

sufficient.

EcoOnline Performance+™ Solar Pool Heating System -- Installation & User Manual

© Copyright 2021 Optex Solar Pty Ltd. All rights strictly reserved.

Page 12

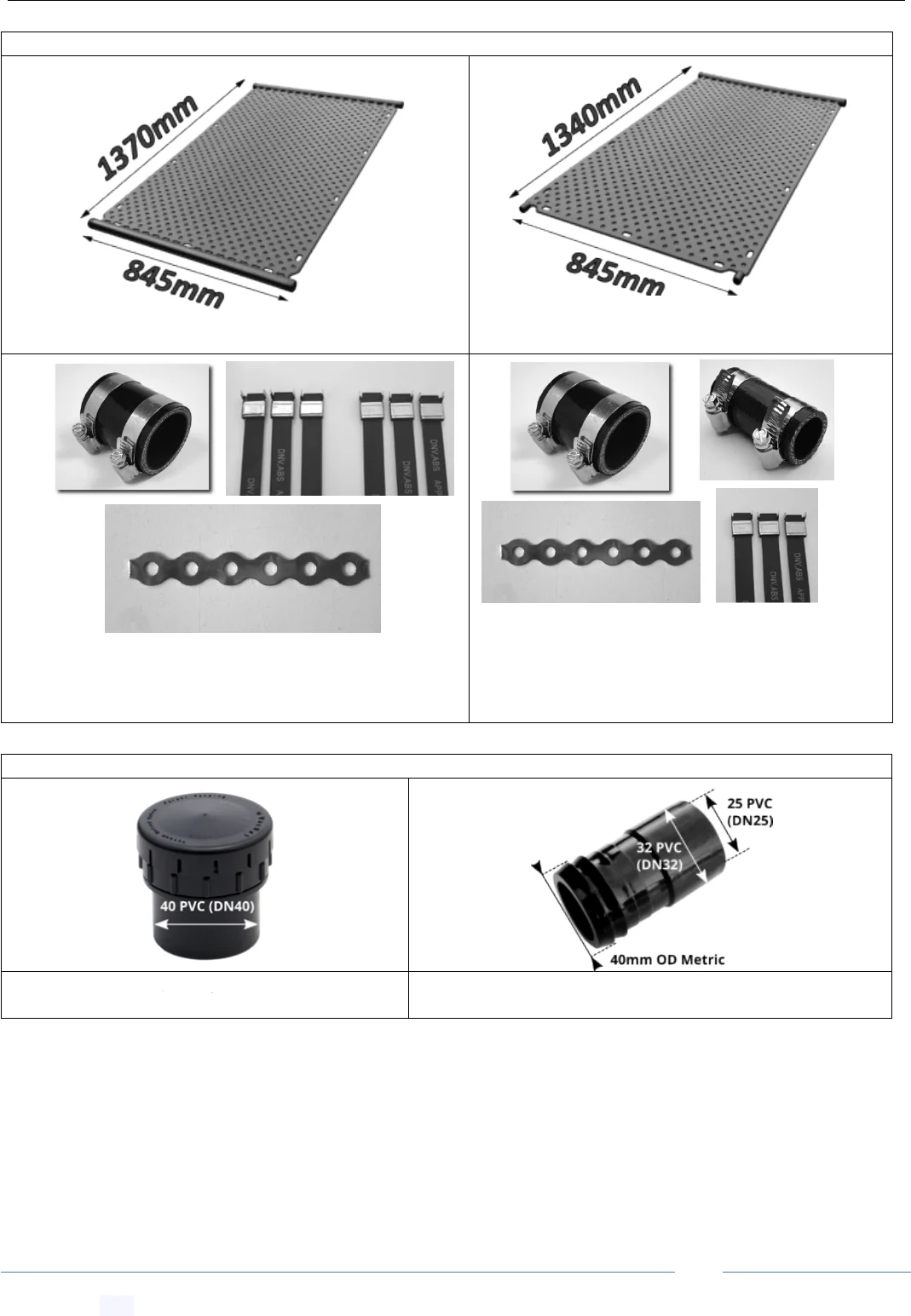

11 Collector Array Components

Create jump link to this section-- Get Link

Interconnect OR Dual Header Panel Kit:

1 × HDPE dual header panel

1 × HDPE interconnect panel

2 × 40mm ID reinforced silicon joiners

4 × Stainless steel hose clamps

6 × 316 Stainless steel straps (black)

1 × 10cm length perforated 316 stainless band

1 × 40mm ID reinforced silicon joiner

1 × 25mm ID reinforced silicon joiner

4 × Stainless steel hose clamps

3 × 316 Stainless steel straps (black)

1 × 10cm length perforated 316 stainless band

Other Collector Array Components

1 × 40 PVC Vacuum breaker valve

(MUST be installed)

2 × 40mm OD hose barb to 25/32 PVC glue socket/take off

EcoOnline Performance+™ Solar Pool Heating System -- Installation & User Manual

© Copyright 2021 Optex Solar Pty Ltd. All rights strictly reserved.

Page 13

12 Additional Required Components (Not Supplied)

Create jump link to this section-- Get Link

You also require some of the following extra items depending on your system. These are available in any plumbing

store. The aluminium angle is available from Capral Ltd. or Ullrich Aluminium Pty. Ltd.

13 Required Tools

Create jump link to this section-- Get Link

- Battery powered hand drill

- Screwdriver

- Safety glasses

- Corking gun (for Silicon glue)

- Hack saw

- Gloves

- Personal Sun/UV protection

- Assorted drill bits

- Power Lead

- Heat Gun

- Tape measure

- Tin snips

- Industrial Ladder

- Needle nose pliers

- Power Lead

- A single 32 PVC (or 20 PVC) Socket – for heat smoothing any misshapen barbs (see below)

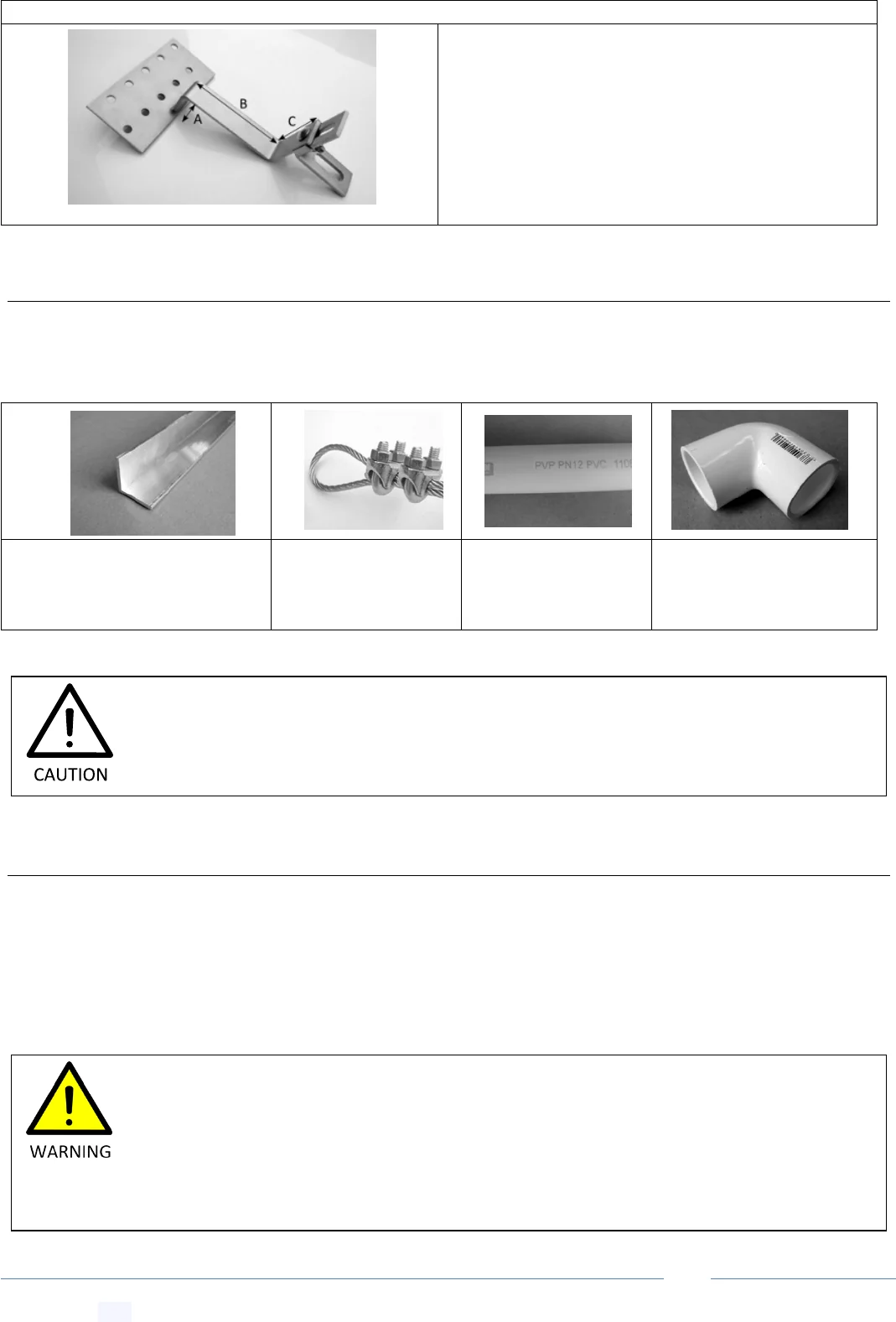

Roof Mounting (Solar roof hook supplied only if requested and purchased)

1 × 304 Stainless solar roof hook (height adjustable)

Dimensions: A = 47.5mm,B = 112mm,C = 60mm

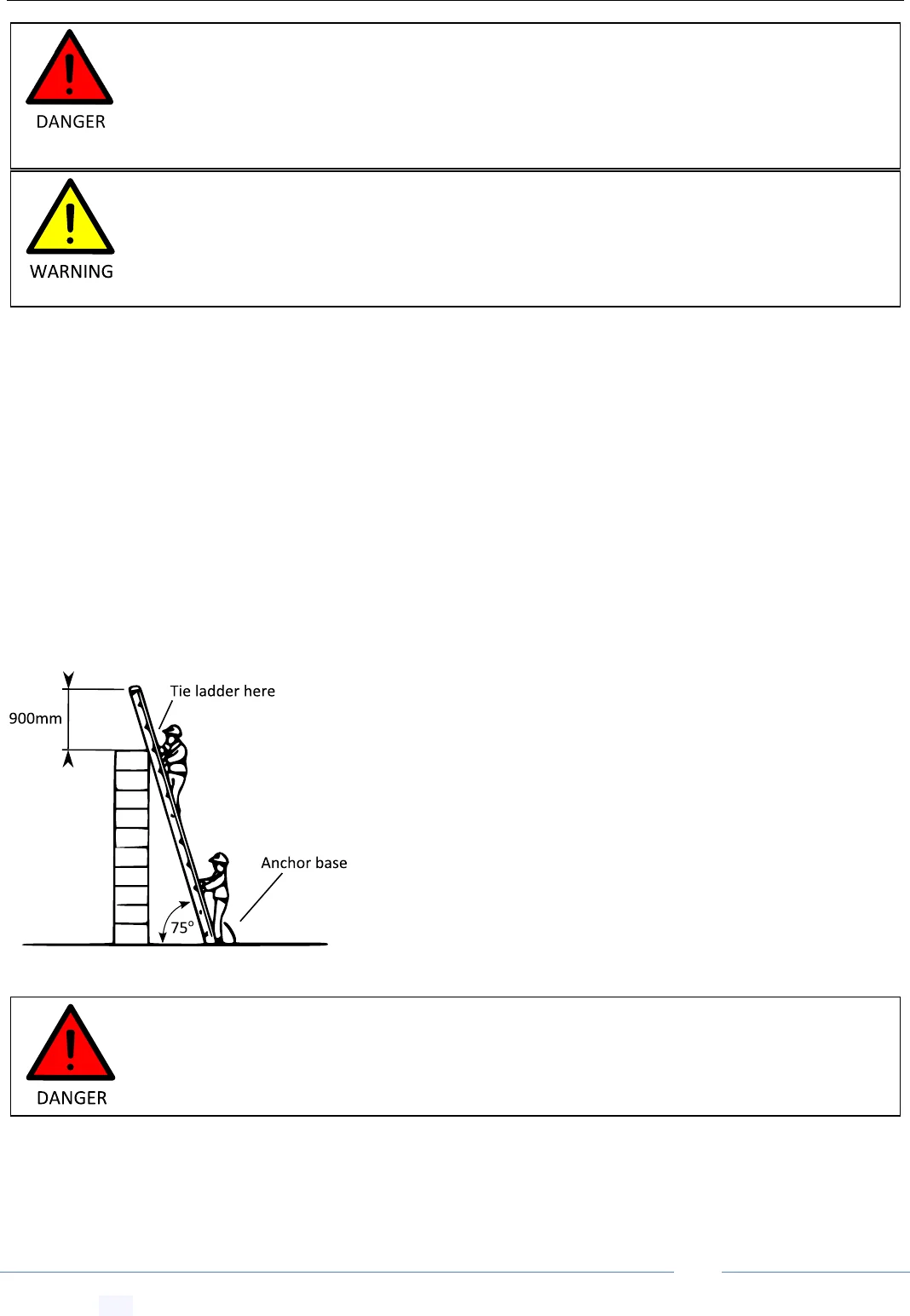

Aluminium angle 30mm x 30mm

x 4mm for metal roofs. 40mm x

40mm x 3mm for tile roofs

4mm stainless steel

cable & four cable ties

per row

PVC piping

(recommend 32 PVC

(DN30) on roof)

PVC bits, including a 32

PVC (DN30) or 20 PVC (DN

20) socket for heat

smoothing barbs

We recommend AS 1477 compliant PVC piping with PN9 pressure rating or greater and

matching PVC fittings be used for all collector array plumbing.

When working with power or hand tools always follow the safety instructions. Wear the

recommended personal protective equipment, such as gloves, safety glasses, respiratory and

hearing projection. Make sure electrical cables are kept away from any water and from

foreign objects which pose a potential cable severing or crushing hazard. When using glues,

solvents or sealing agents make sure you know and seek the proper first aid in case of an

accident.

EcoOnline Performance+™ Solar Pool Heating System -- Installation & User Manual

© Copyright 2021 Optex Solar Pty Ltd. All rights strictly reserved.

Page 14

14 Safety When Working at Heights

Create jump link to this section-- Get Link

The installer should always take the necessary safety precautions:

Choose an appropriate day: cool, dry, calm and partly cloudy.

Plan out your install: make sure you have all required components, tools and have plenty of allocated time.

Only work at heights when you are well rested and alert.

Never work alone, always work with at least one other person.

Always use a safety harness or fall arrest system attached to appropriate roof anchor points.

Wear clothes that fit well but that do not restrict movement.

Use proper non-slip shoes.

Use sunscreen.

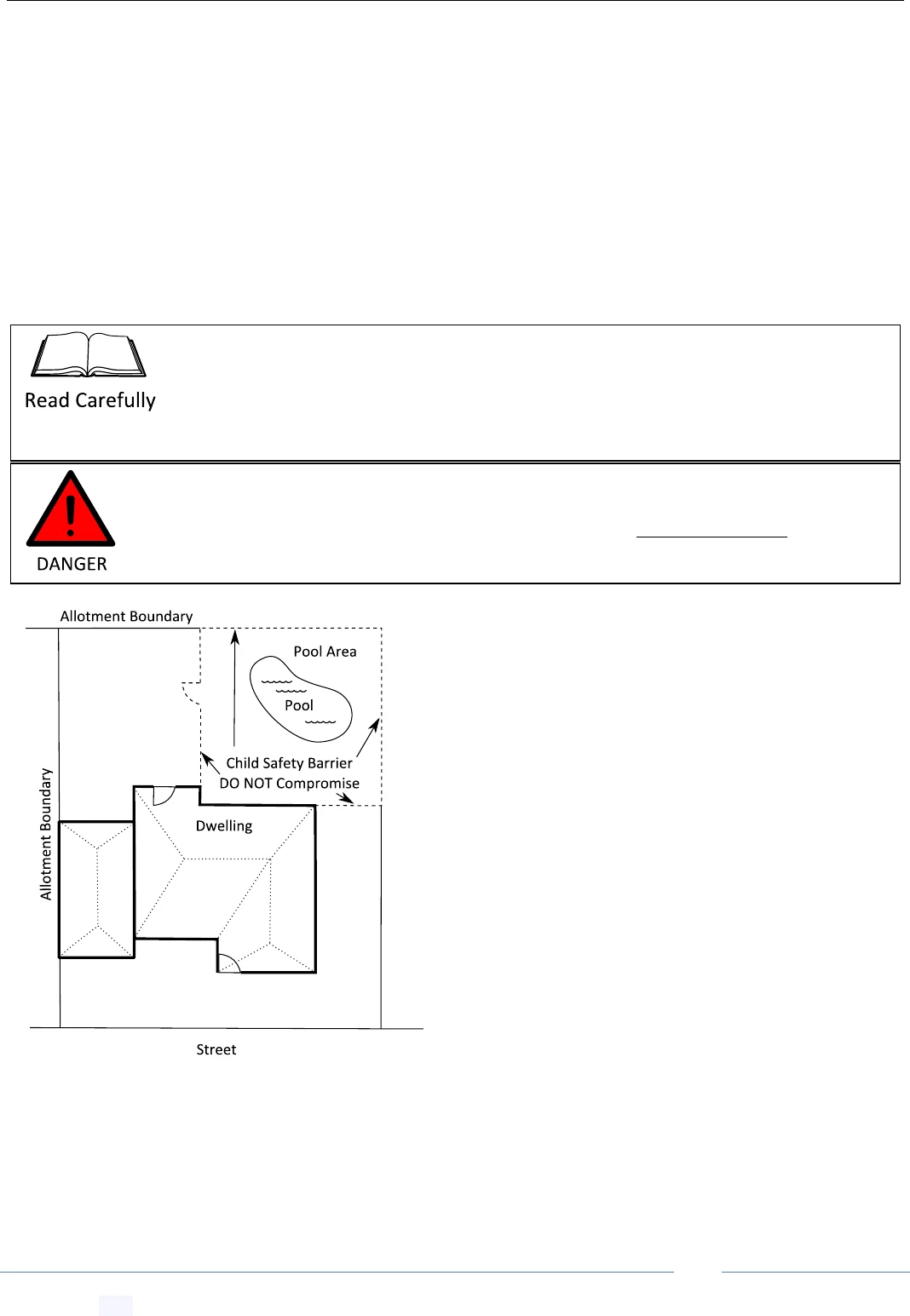

14.1 Ladder Safety

Create jump link to this section-- Get Link

The chance of a falling from a ladder should never be

underestimated. Use only solid industrial grade ladders in good repair

that have been checked for faults.

Note: even a small unexpected movement of the ladder, such as a

small slip, can cause loss of balance and result in a fall.

The ladder should be placed on solid ground and should ALWAYS be

securely anchored at the base and secured at the top to prevent

slipping.

WHEN WORKING AT HEIGHTS - SAFETY COMES FIRST. A person can easily fall off a ladder or

roof and be seriously injured. For installations on a roof pitch greater than 22° and/or a double

story house we strongly recommend a highly competent professional installer install your solar

collector array. We strongly recommend the installer invests in roof safety guard rails and a

safety harness system, especially for DIY applications.

Solar panels should not be mounted in windy or gusty conditions; a panel can easily be caught

in the wind and cause a loss of balance and result in a fall.

The collectors can be walked on without damage. Take extreme care to use non-slip shoes and

never walk on wet collectors, especially on installations with any significant pitch. HDPE

material is a slippery and waxy surface. If the collectors need to be walked on for mounting

purposes, ALWAYS use a safety harness and fall arrest system.

EcoOnline Performance+™ Solar Pool Heating System -- Installation & User Manual

© Copyright 2021 Optex Solar Pty Ltd. All rights strictly reserved.

Page 15

15 Choosing a Place to Install the Collector Array

Create jump link to this section-- Get Link

When choosing a location for your collector array you should consider:

Shading - the collector array should receive no shading between the hours 10am to 4pm.

Wind - the collector array should be mounted in a relatively sheltered location or with appropriate wind

proofing.

Distant to pool/spa - collectors should be as close as possible to your pool (or spa).

Direction - collectors should preferably face north for maximum heat collection; however the collector

array can also face any angle between East to West.

Mounting elevation - this depends on the desired seasonal heat collection. Flatter elevations (< 45°) collect

more heat in the summer while installations closer to vertical (> 45°) produce more heat during

spring/autumn.

The figure to the left shows an example of a Child Safety

Barrier marked with a dashed line. A collector array should

not be mounted near the Child Safety Barrier - both on the

inside and outside of the Pool Area unless proper

clearances are observed. Consult your Local Government,

The Building Commission or SPASA for details regarding

pool safety barriers in your state. Please keep up to date

with regulations as they change over time. For more

information see, AUSTRALIAN STANDARDS 1926.1 2007

AND 1926.2 2007 FOR POOL SAFETY BARRIERS.

Do not install the collectors leaning against the

outside of a Child Safety Barrier so as to create a climbable

object for children to access the pool or spa.

Collectors installed inside the pool area in front of a

boundary fence must be offset away from the boundary

fence with the proper clearance from the top of the fence

so as not to provide a foothold for a child climbing into the

pool area.

Do not install the collectors too close to the inside of a Child Safety Barrier so as to provide foot or

handholds from the outside of the barrier.

For spa baths and above ground pools do not lean the collector array against the side of the spa or pool so as

to create a ramp or climbable object.

For ground mounted arrays, under no circumstances should a collector array be mounted in

anyway so as to compromise the effectiveness of a pool or spa Child Safety Barrier.

The collector array can face anywhere from West to East, with an optimal orientation of

North-west for most areas. South facing orientations are generally not recommended,

unless the roof pitch is quite flat < 5˚ for southern states and < 15˚ for northern states.

EcoOnline Performance+™ Solar Pool Heating System -- Installation & User Manual

© Copyright 2021 Optex Solar Pty Ltd. All rights strictly reserved.

Page 16

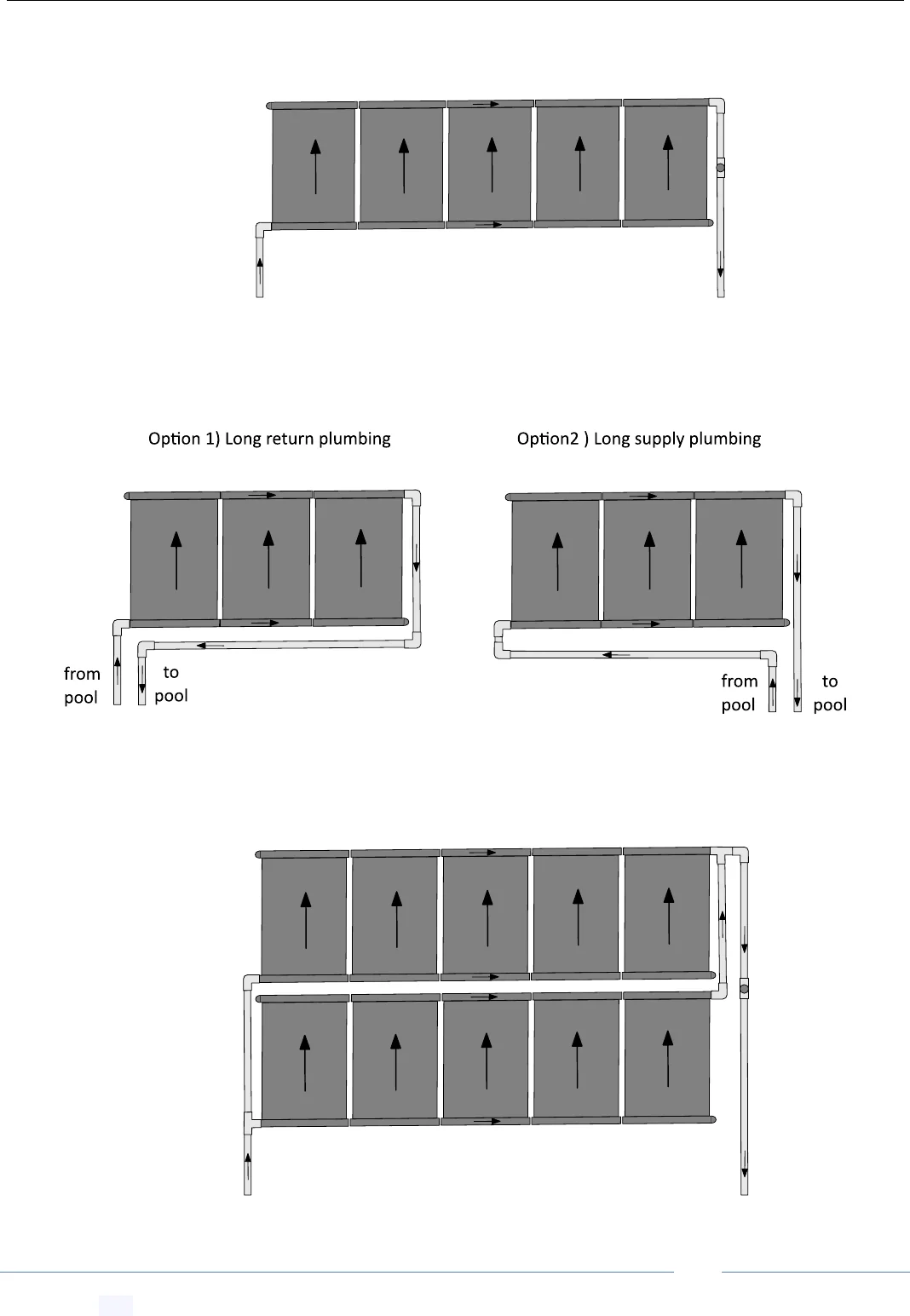

16 Collector Water Flow Configurations

Create jump link to this section-- Get Link

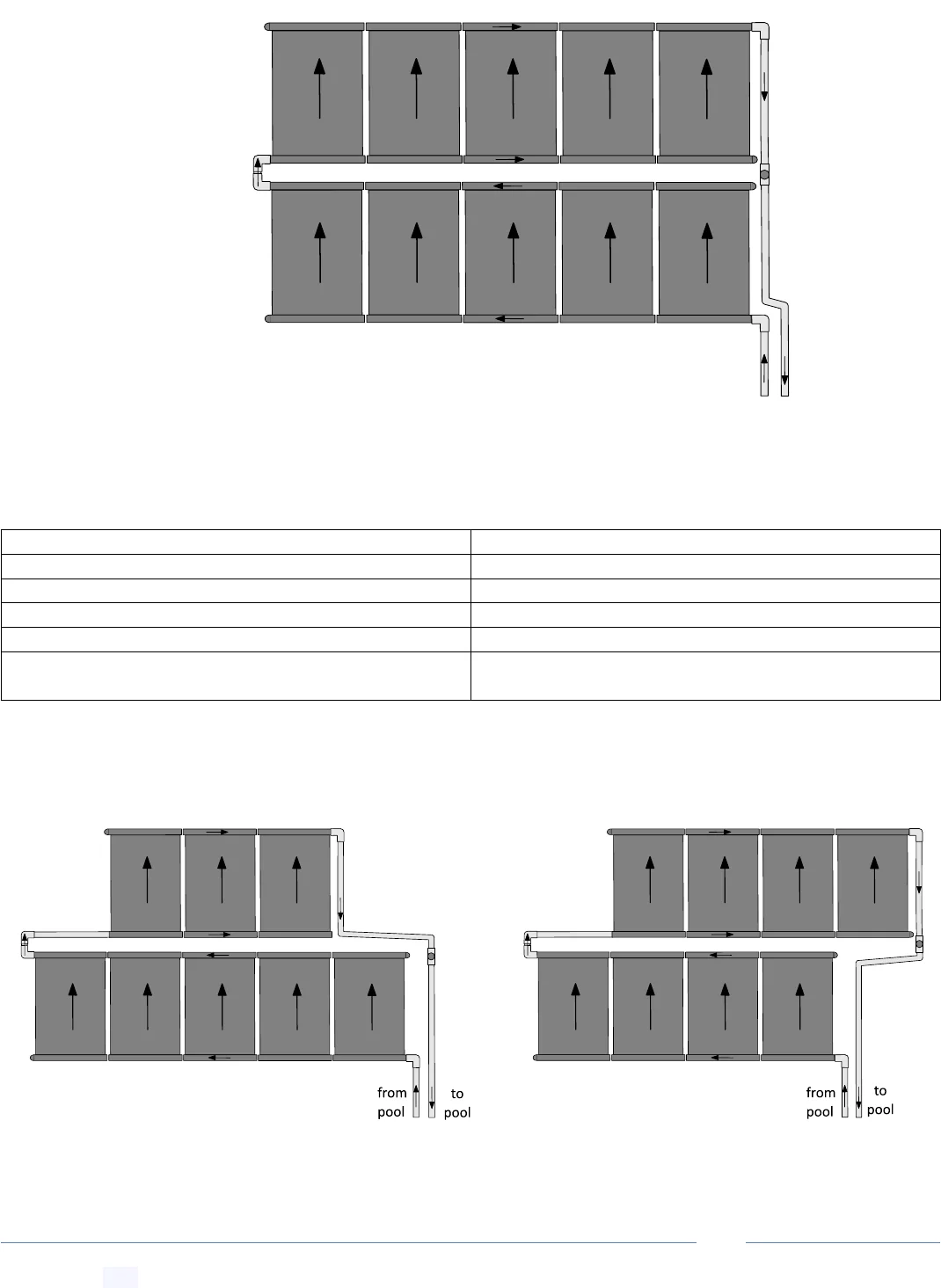

16.1 Dual Header Panel Single Row Flow Configuration

Create jump link to this section-- Get Link

16.2 Supply and Return Plumbing Options

Create jump link to this section-- Get Link

16.3 Dual Header Panel Two Rows In-Parallel Configuration

Create jump link to this section-- Get Link

from

pool

to

pool

Suggested

configuration

limits:

~100L/min

~14 Panels

to

pool

from

pool

Suggested

configuration

limits:

~200L/min

~28 Panels

~45 Roof Pitch

o

EcoOnline Performance+™ Solar Pool Heating System -- Installation & User Manual

© Copyright 2021 Optex Solar Pty Ltd. All rights strictly reserved.

Page 17

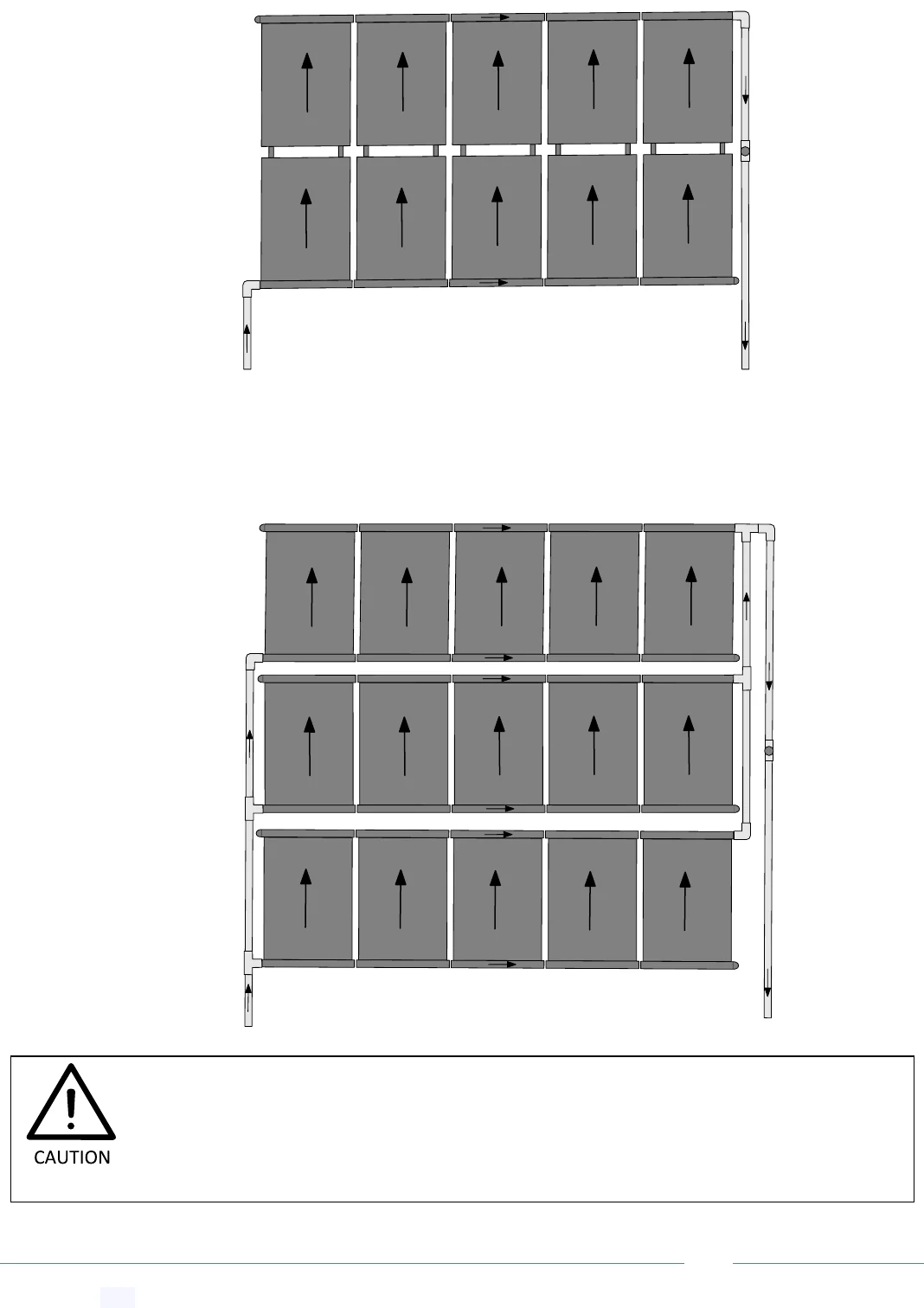

16.4 Two Row Serpentine Flow Configuration

Create jump link to this section-- Get Link

16.5 Parallel vs Serpentine Flow Configurations

Create jump link to this section-- Get Link

Parallel Configuration 17.3 (Recommended)

Serpentine 17.4 (Max: 100L/min, 20 Panels)

Splits flow - lower panel pressures

Higher panel pressures

Harder to plumb, more PVC bits

Easier to plumb but headers must be level

Better for larger panel per row arrays

Okay for arrays ≤10 per row

Okay for any pitch 2˚ (flat) - 90˚ (fence)

Okay for standard roof pitches between 5˚ to 35˚

Use for three or more row configurations

Not suited for three row configurations

(unless array has ≤ 20 panels)

16.6 Serpentine Flow for a Trapezoid or Parallelogram Array

Create jump link to this section-- Get Link

to

pool

from

pool

Suggested

configuration

limits:

~200L/min

~28 Panels

~35 Roof Pitch

o

EcoOnline Performance+™ Solar Pool Heating System -- Installation & User Manual

© Copyright 2021 Optex Solar Pty Ltd. All rights strictly reserved.

Page 18

16.7 Interconnect Panel Flow Configuration

Create jump link to this section-- Get Link

16.8 Three Row In-Parallel Flow Configuration

Create jump link to this section-- Get Link

to

pool

from

pool

Suggested

configuration

limits:

~100L/min

~14 Panels

~45 Roof Pitch

o

to

pool

from

pool

Suggested

configuration

limits:

~300L/min

~42 Panels

~20 Roof Pitch

o

Please note: the bottom row of panels in a three row (or more) configuration installed on a

roof pitch greater than 20˚ will experience greater pressures. When carrying out the

Pressure Optimization Procedure in Section 27, we recommend setting the lowest positive

pressure possible.

EcoOnline Performance+™ Solar Pool Heating System -- Installation & User Manual

© Copyright 2021 Optex Solar Pty Ltd. All rights strictly reserved.

Page 19

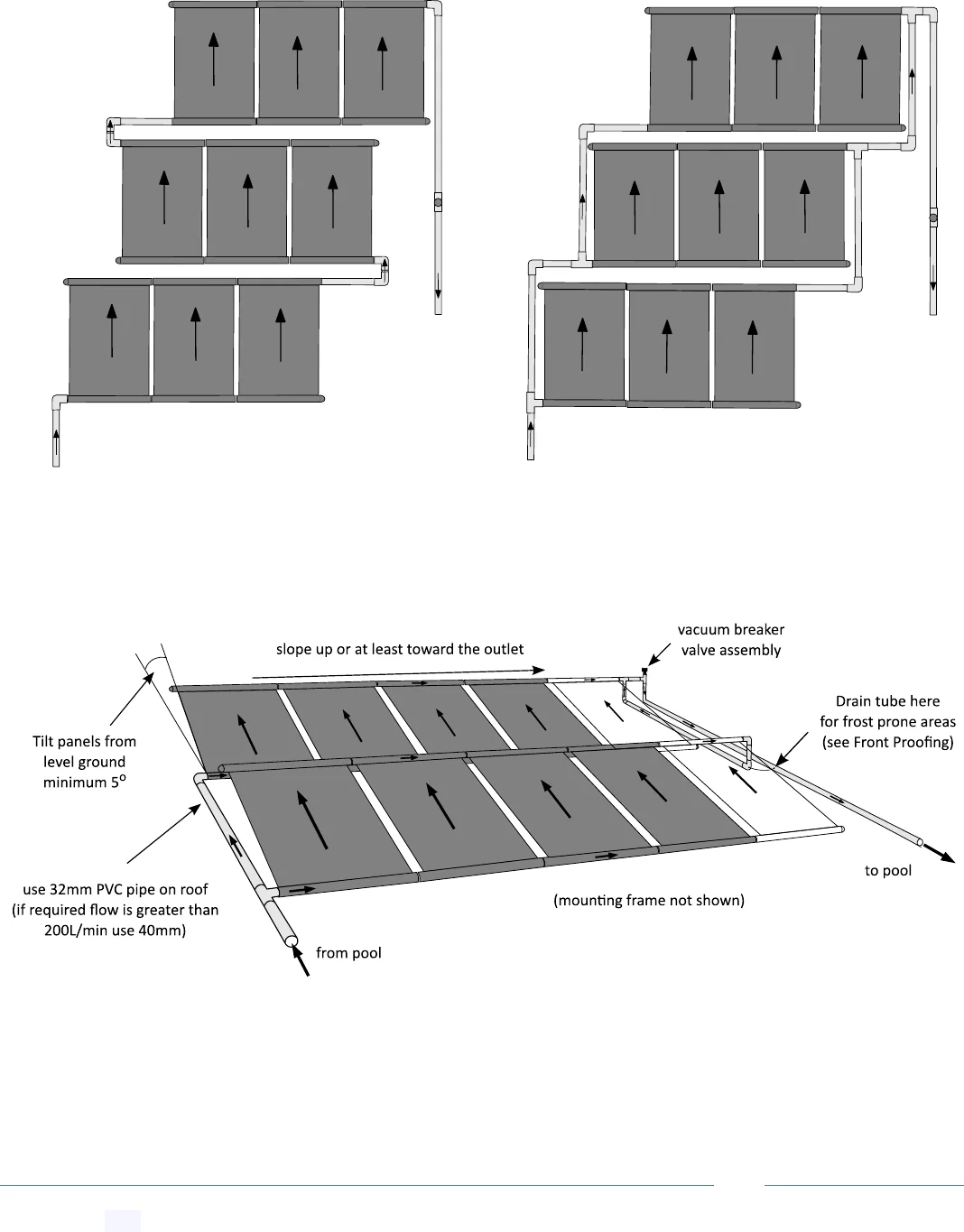

16.9 Staggered Array Flow Configurations

Create jump link to this section-- Get Link

16.10 Level Ground Mounting Configurations

Create jump link to this section-- Get Link

to

pool

from

pool

to

pool

from

pool

Suggested

configuration

limits:

~100L/min

~15 Panels

~20 Roof Pitch

Suggested

configuration

limits:

~300L/min

~42 Panels

~20 Roof Pitch

o

o

EcoOnline Performance+™ Solar Pool Heating System -- Installation & User Manual

© Copyright 2021 Optex Solar Pty Ltd. All rights strictly reserved.

Page 20

16.11 Split Array at Similar Height Levels

Create jump link to this section-- Get Link

16.12 Split Array at Substantially Different Heights

Create jump link to this section-- Get Link

For ground mounted arrays, under no circumstances should a collector array be mounted in

anyway so as to compromise the effectiveness of a pool or spa Child Safety Barrier.

Split collector arrays with a vertical height difference no more than 1m can use the

above configuration. Both array should be installed facing the same direction - or have

no more than 30˚ compass facing difference between them. In this later case the

temperature sensor should be installed at an angle that is an average of the two

collector array compass facing directions.

Why? Depending on the location of the roof sensor the controller could turn the system

on with one bank of collectors in full shade.

EcoOnline Performance+™ Solar Pool Heating System -- Installation & User Manual

© Copyright 2021 Optex Solar Pty Ltd. All rights strictly reserved.

Page 21

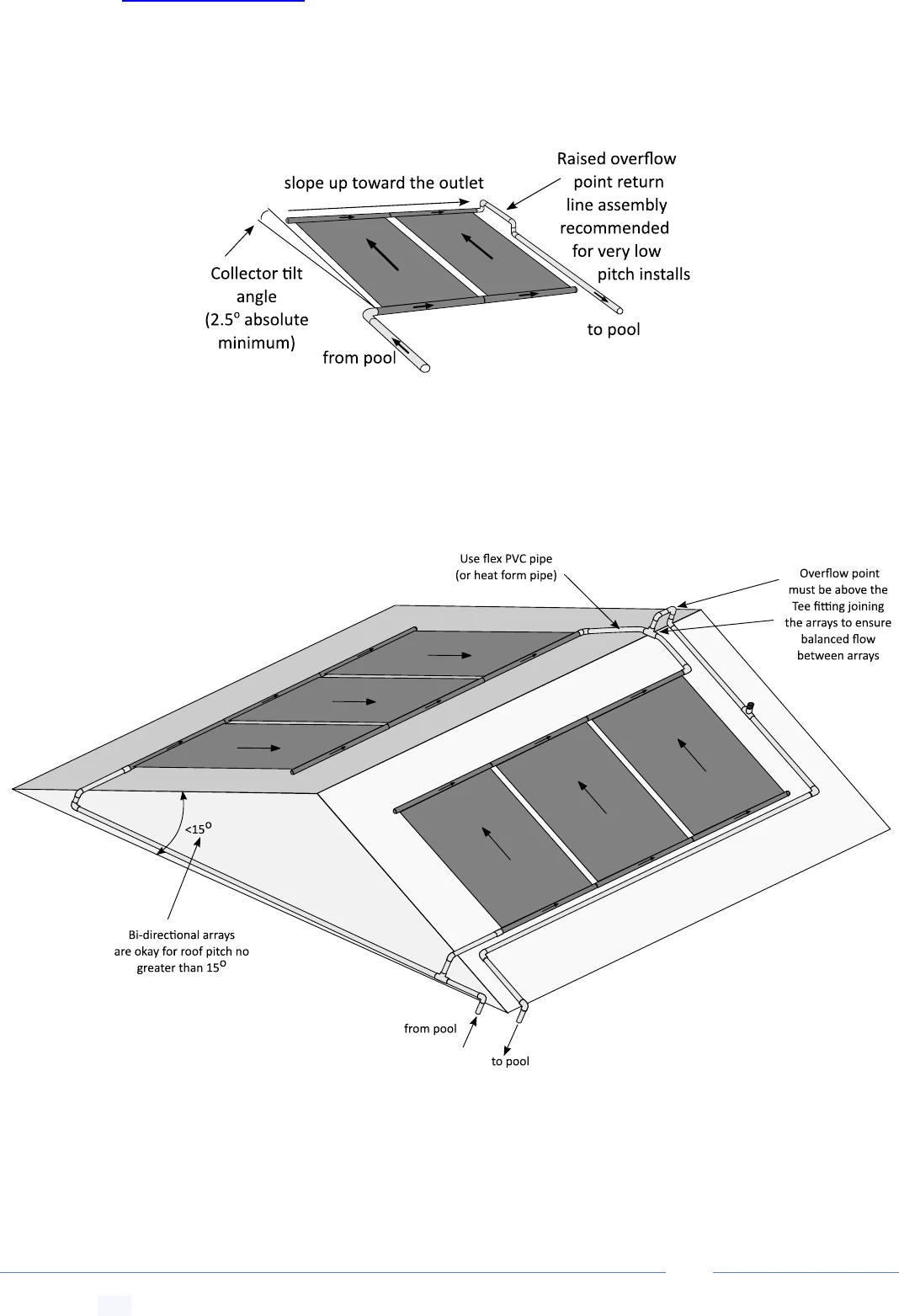

16.13 Bridging Obstructions, Expansion Joiners and Uneven Rows

Create jump link to this section-- Get Link

to

pool

from

pool

Air conditioner,

skylight or vent

32PVC bridging pipe section

( 2 x barb adapter + pipe)

PVC bridging pipe

section for uneven

number rows

thermal expension/contraction joiner

for array > 15 panels in length

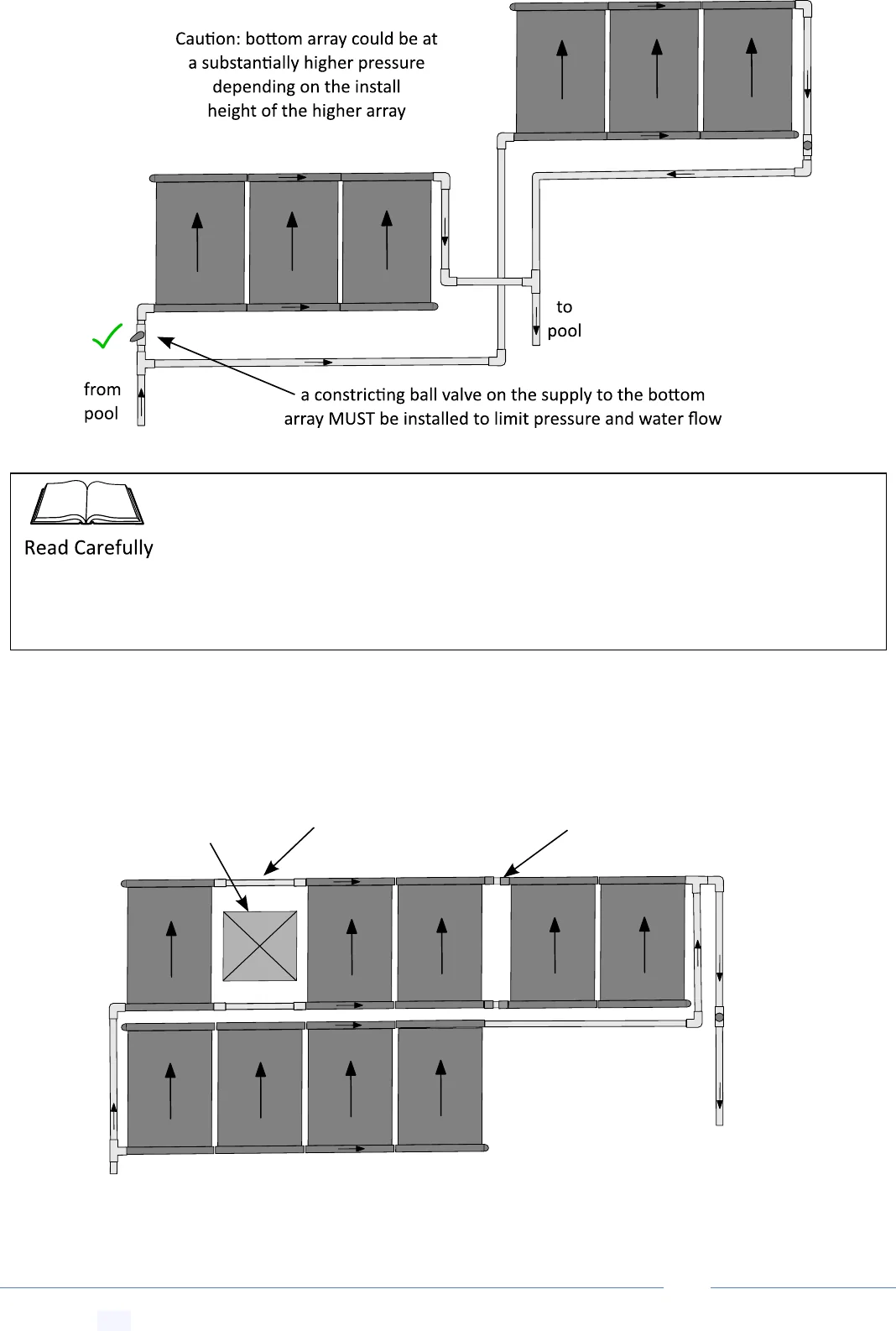

Split collector arrays with a vertical height difference of greater than 1m MUST use the

above configuration with a constricting ball valve installed on the supply to the bottom

array to protect it from excessive pressure.

Why? Without the constricting ball valve the bottom array would receive all the water

flow.

EcoOnline Performance+™ Solar Pool Heating System -- Installation & User Manual

© Copyright 2021 Optex Solar Pty Ltd. All rights strictly reserved.

Page 22

Please contact info@EcoOnline.com.au or visit our store for the special 316 slide expansion joiner for arrays that are

greater than 14 panels in a single row.

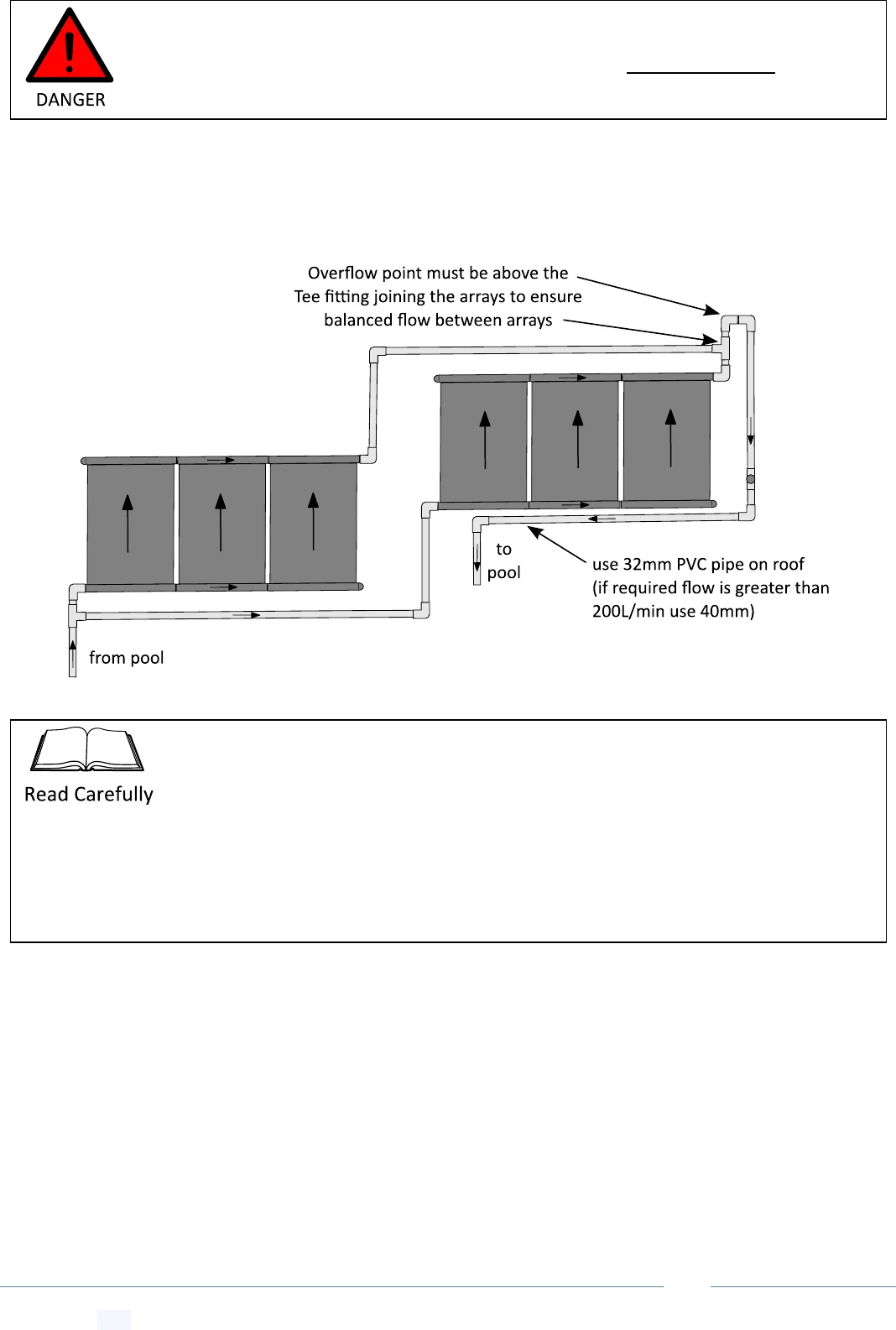

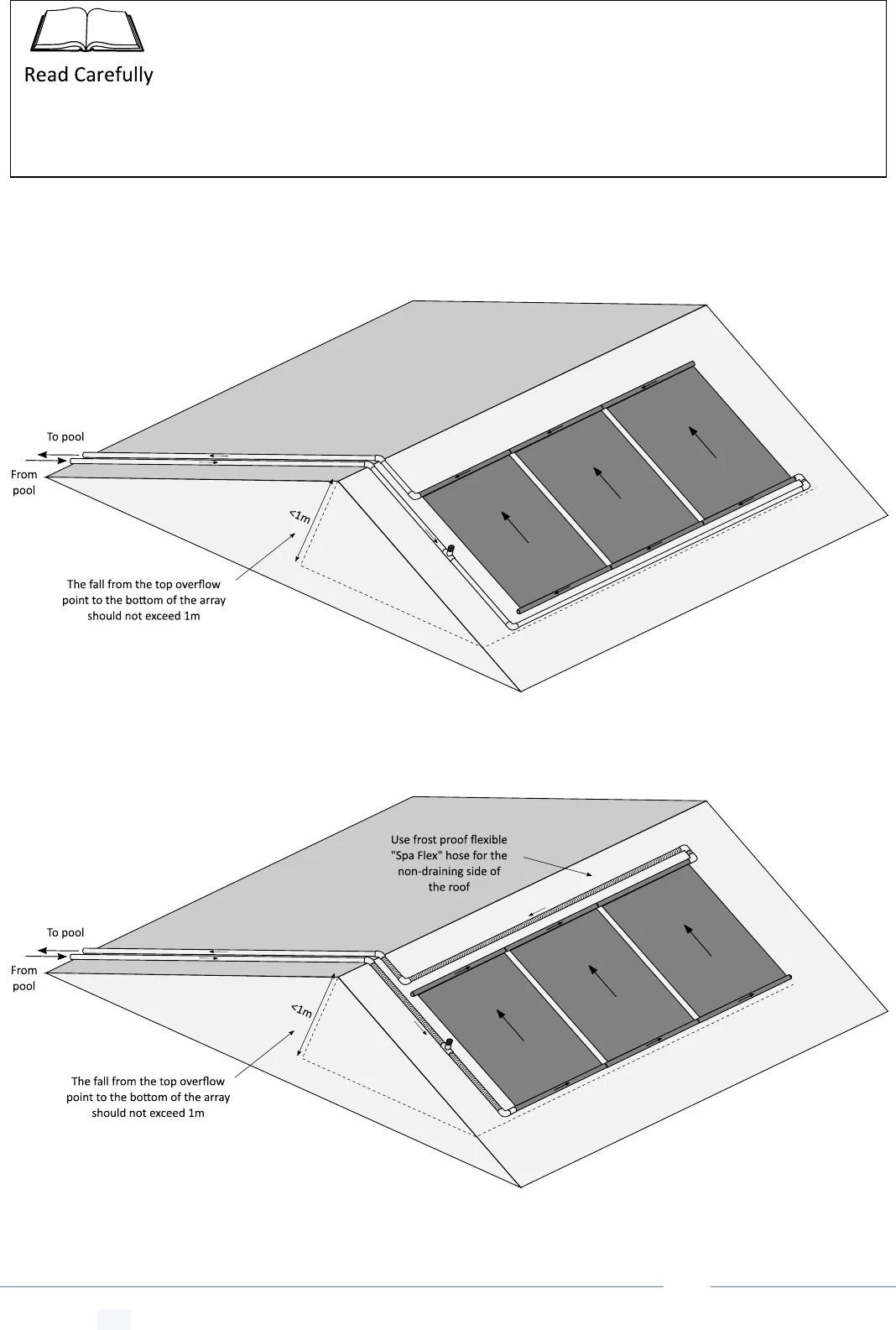

16.14 Return Line Configuration for Low Pitch Roof

Create jump link to this section-- Get Link

16.15 Preferred Bi-Directional Flow Configuration

Create jump link to this section-- Get Link

EcoOnline Performance+™ Solar Pool Heating System -- Installation & User Manual

© Copyright 2021 Optex Solar Pty Ltd. All rights strictly reserved.

Page 23

16.16 Top Feed Flow Configuration for Non-Frost Areas

Create jump link to this section-- Get Link

16.17 Top Feed Flow Configuration for Frost Areas

Create jump link to this section-- Get Link

Collector arrays that face opposing compass directions are not recommended unless

the roof pitch is less than ~15˚. In this case the temperature sensor should be installed

at an angle that is an average of the two collector array directions.

Why? Depending on the location of the roof sensor the controller could turn the system

on with one bank of collectors in full shade.

EcoOnline Performance+™ Solar Pool Heating System -- Installation & User Manual

© Copyright 2021 Optex Solar Pty Ltd. All rights strictly reserved.

Page 24

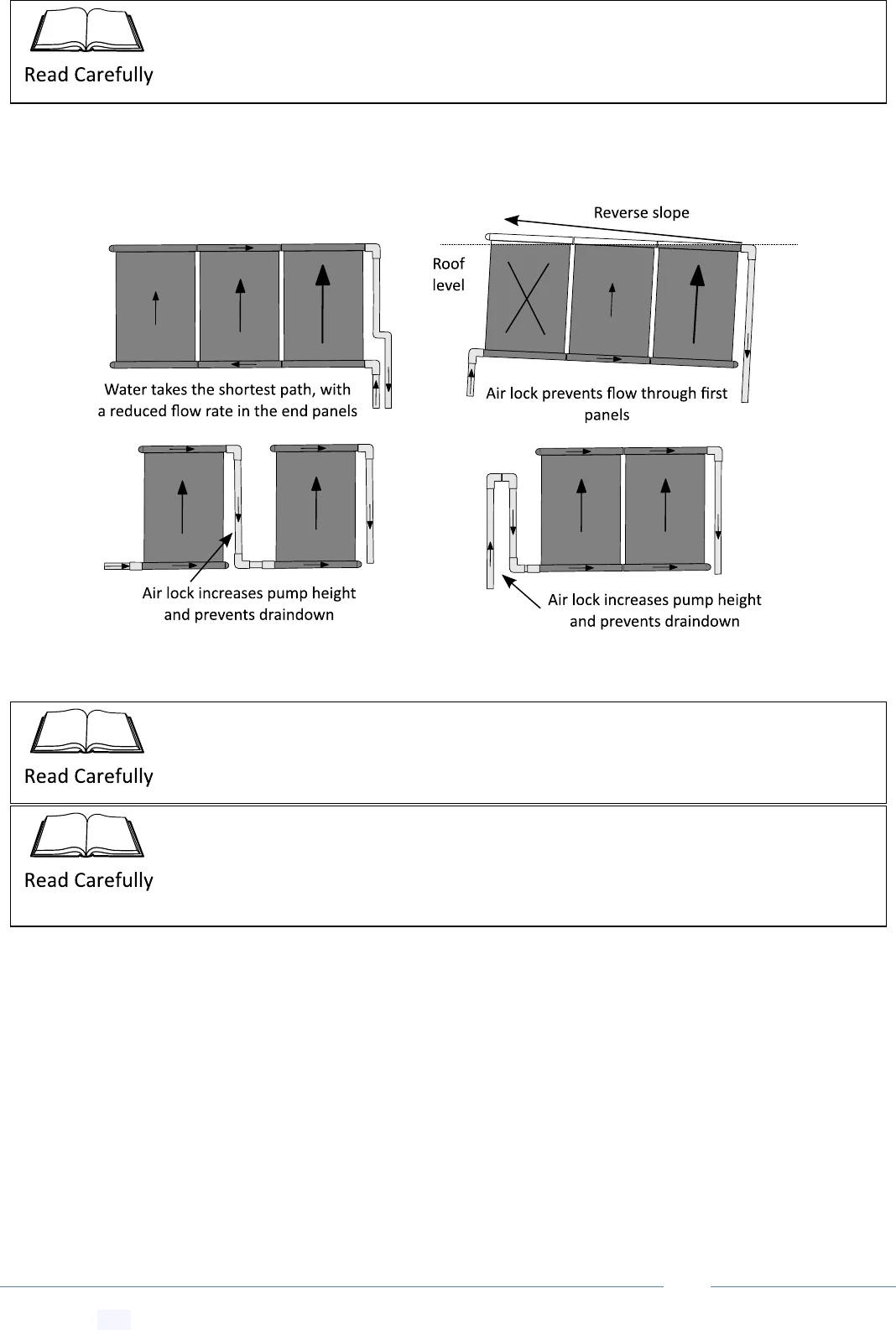

16.18 Plumbing Flow Configurations Not Recommended

Create jump link to this section-- Get Link

To make sure all air bubbles are evacuated upon filling collector should be installed

with a minimum recommended pitch of 3-5˚.

Ideally the collector array top header pipe should have a 1 to 2° upward slope toward

the outlet, to make sure all air is automatically removed from the entire array upon

filling. This is especially important for system with row containing 10 or more panels.

For frost prone areas the supply and return lines that runs over the top of the roof MUST

be run using UV rated “Spa Flex” hose (note Spa Flex hose requires special flexible PVC

glue).

EcoOnline Performance+™ Solar Pool Heating System -- Installation & User Manual

© Copyright 2021 Optex Solar Pty Ltd. All rights strictly reserved.

Page 25

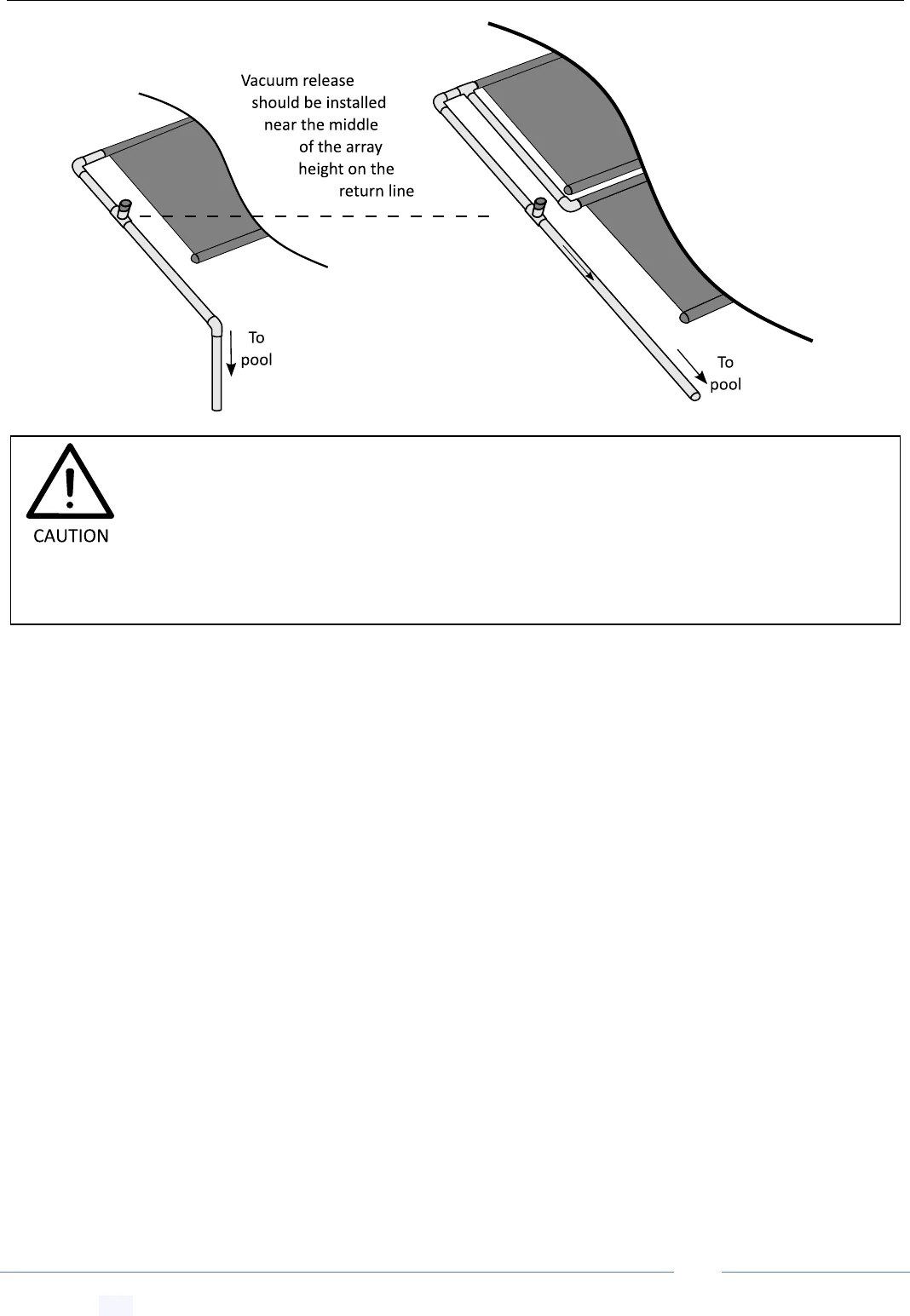

17 Vacuum Release Location

Create jump link to this section-- Get Link

The vacuum release is a critical part of the system and must be installed for all collector

array greater than 0.5m above the water level.

Why? System without a vacuum release will experience large negative pressure working

forces as the pump stops and the water wants to fall back. The vacuum release on the

return line and the non-return on the supply line stop these pressure fluctuations.

EcoOnline Performance+™ Solar Pool Heating System -- Installation & User Manual

© Copyright 2021 Optex Solar Pty Ltd. All rights strictly reserved.

Page 26

18 Collector Panel Plumbing Connections

Create jump link to this section-- Get Link

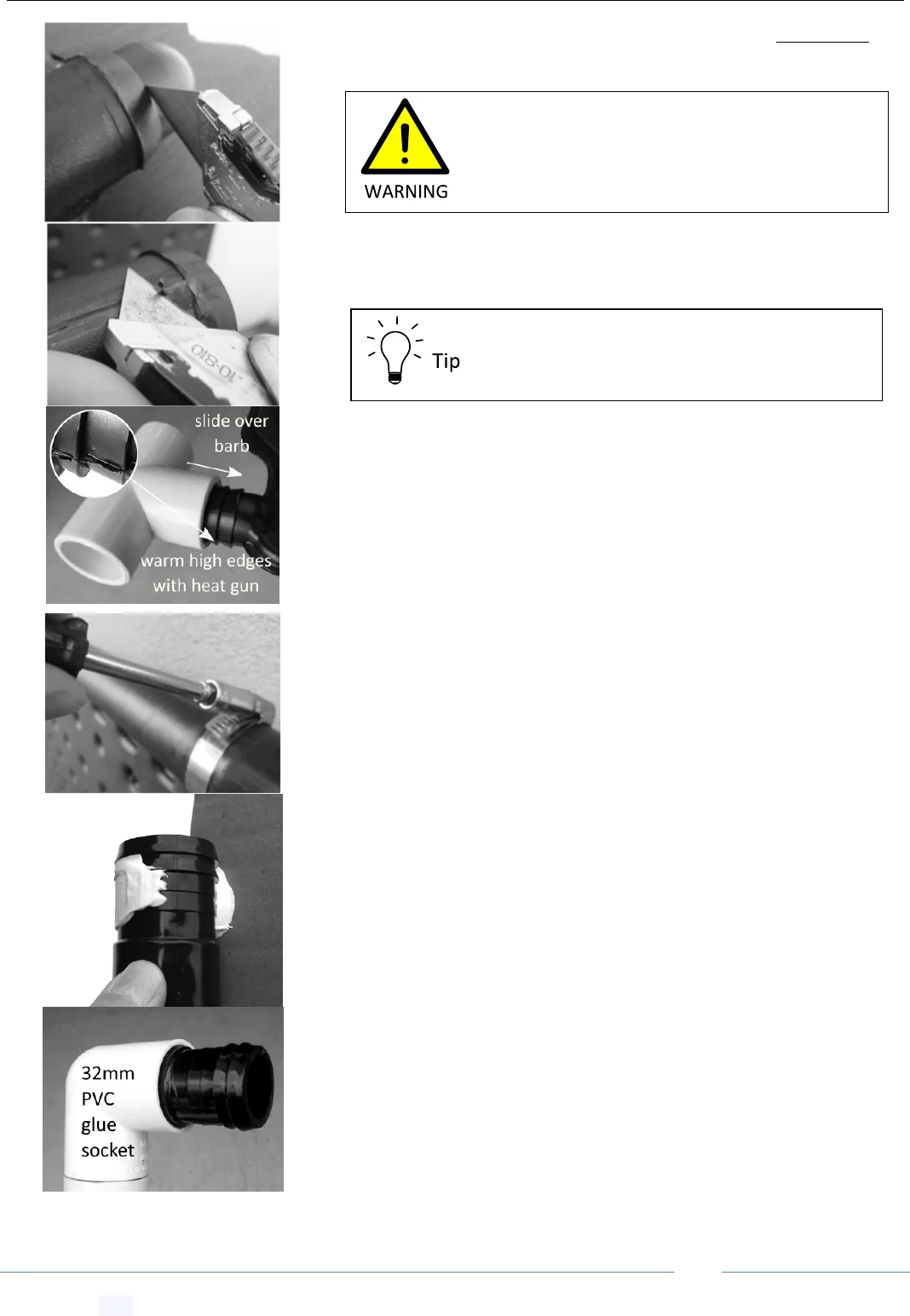

BEFORE CUTTING - put aside two collectors per row with undamaged

end caps. For all remaining collectors cut the single end cap off using a

sharp blade or hacksaw.

Check all collector pipe connections for raised edges or grooves on the

weld lines which could channel water and cause leaks. Clean these up

using a blade and/or a heat gun on a high setting.

Check all barb edges are smooth and spherical to seal properly. For any

high or low points, warm the barb edge with a heat gun on high at 450°C

for 3-4 seconds, then slide over a 32 PVC (DN30) socket or 20 PVC (DN20)

socket for the smaller interconnect barb – this will knock down any high

points.

When installing silicon joiners the hose clamp band should be at the end

of the silicon joiner and not on the connector barbs. HAND TIGHTEN ONLY

using with an 8mm hex socket. Do not glue in silicon joiners. (Pinhole

leaks can be sealed with a little silicon). You may need to slightly re-

tighten these with cool water running through the collectors at a later

stage, as HDPE has a high thermal contraction.

The barb end of inlet/outlet PVC adapter should be glued into the 40mm

silicon joiner with any neutral cure silicon as shown.

Why? PVC barbs can soften at extreme roof stagnation temperatures and

contract slightly with clamp pressure. HDPE, on the other hand, will not

soften significantly at the maximum roof stagnation temperature of ~80˚C.

The non-barb end of inlet/outlet PVC adapter should be glued into 32 PVC

(DN30) sockets.

Note: some 32 PVC (DN30) socket brands are non-standard and are quite

loose with our adapters, if so apply a layer of PVC glue and let dry for 1

hour prior to final socket gluing or use a filler PVC glue.

Laceration hazard: Always cut away from your

body and ensure no parts of the body are in front

of the cutting blade.

Any misshapen barbs can be warmed to 150°C

with a heat gun to reform.

EcoOnline Performance+™ Solar Pool Heating System -- Installation & User Manual

© Copyright 2021 Optex Solar Pty Ltd. All rights strictly reserved.

Page 27

18.1 PVC Pipe Roof Fixings

Create jump link to this section-- Get Link

19 Array Roof Fixing Configurations

Create jump link to this section-- Get Link

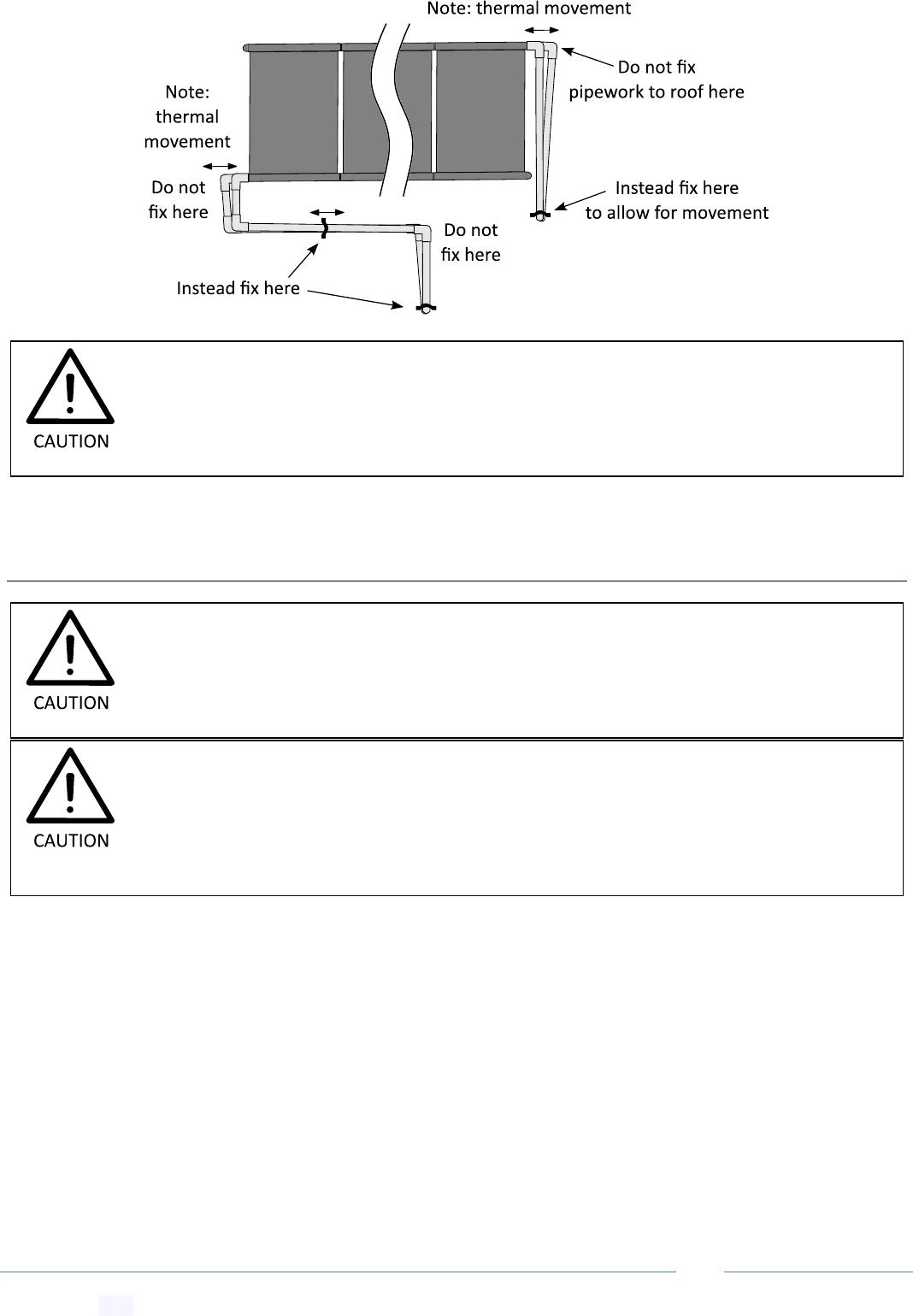

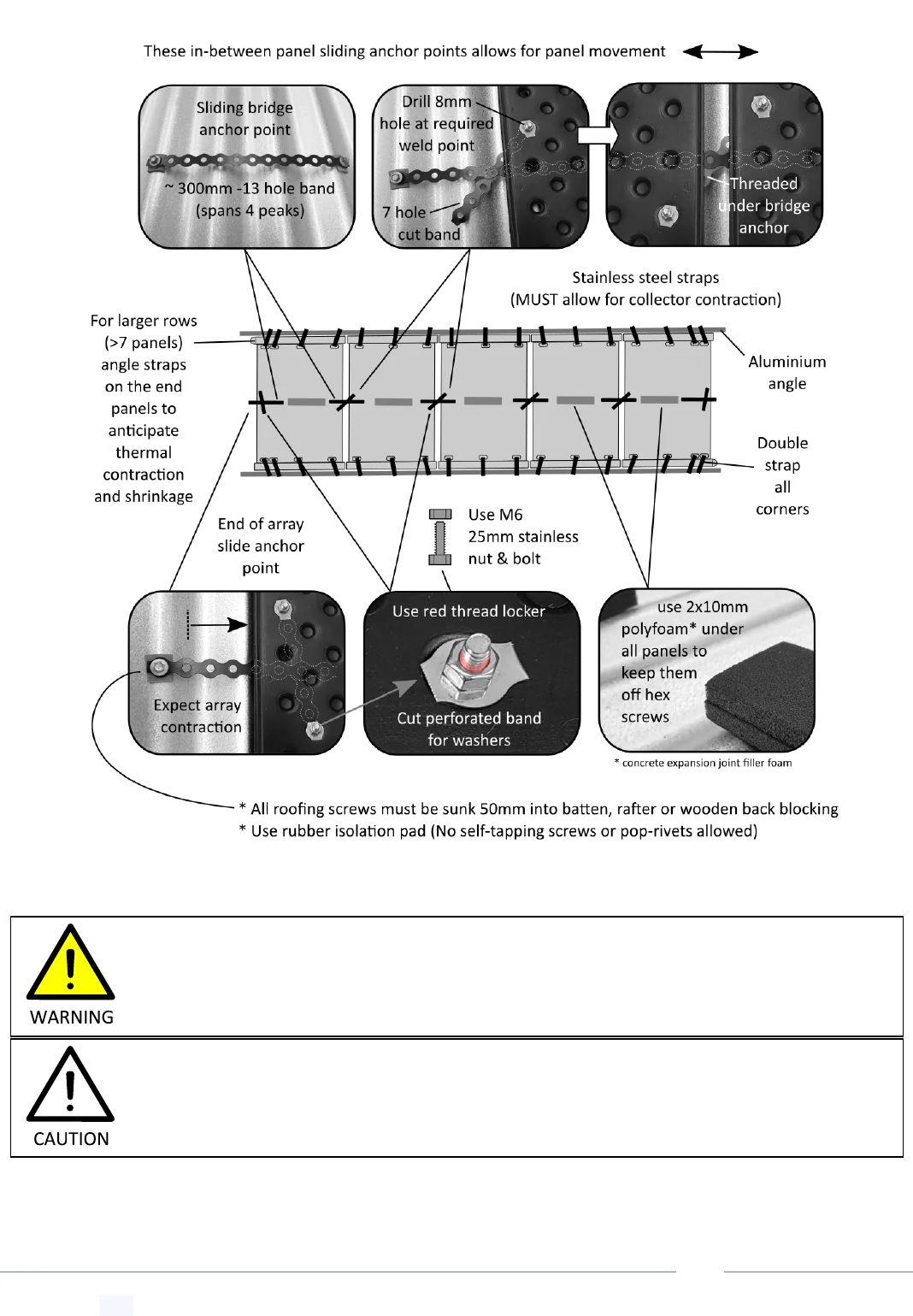

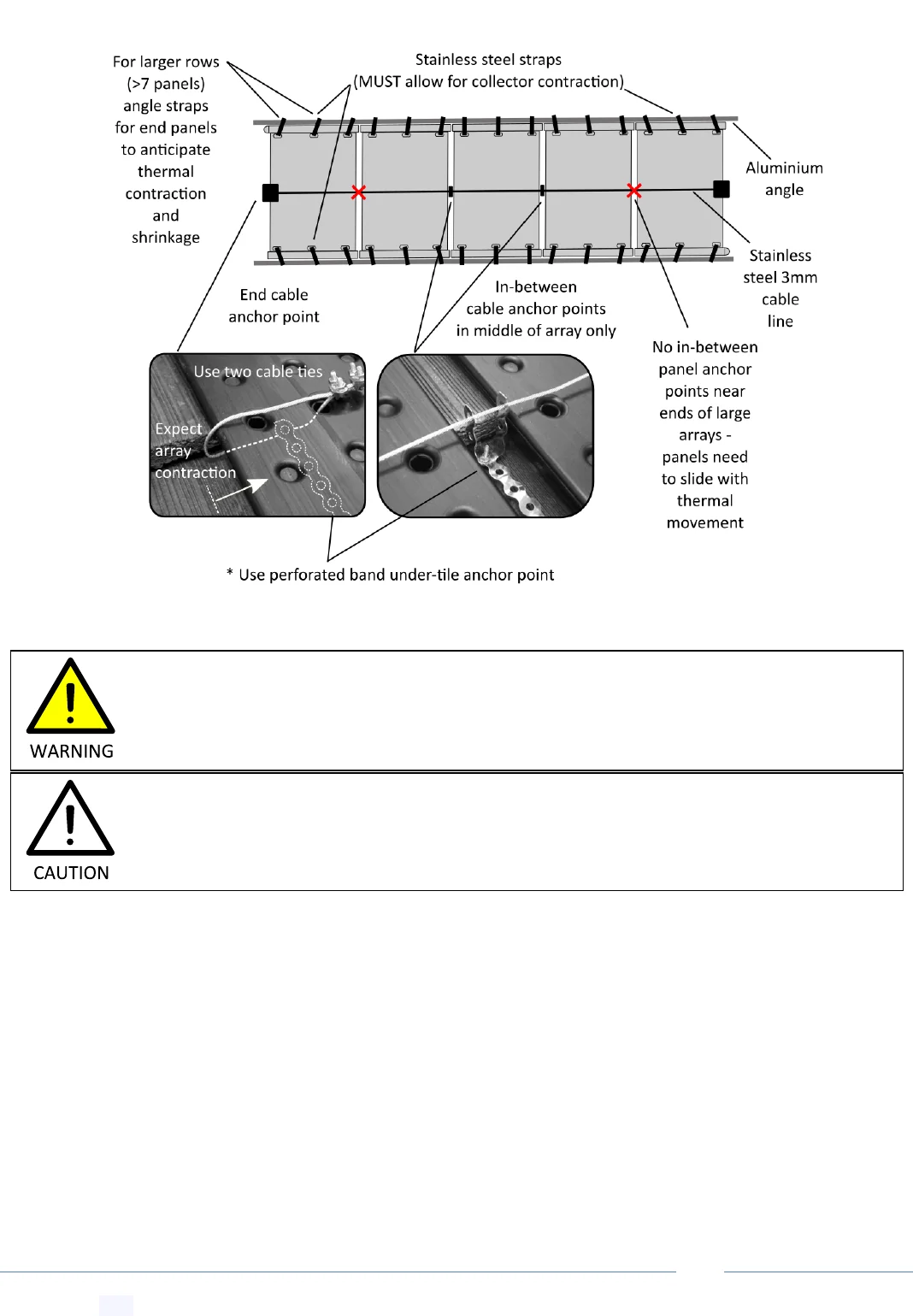

Note the high thermal contraction and natural relaxation of HDPE: Collectors will contact (in

length) by up to 10mm over time and 12mm thermally across temperature extremes. Hence

any fixing means must account for an ultimate contraction of 22mm in length per panel.

Key design principles when choosing a roof mounting means:

1) Consider the high thermal contraction of HDPE

2) Panels should be as low down on the roof as possible to prevent the wind from

catching the underside of panels

3) The stainless steel straps must allow for thermal movement of panels.

Note the large thermal movement in the array inlets and outlets (depending on how panels

you have in one row). PVC pipe work should NOT be fixed to the roof near the inlets and

outlets, but should be allowed to move with the collector array.

EcoOnline Performance+™ Solar Pool Heating System -- Installation & User Manual

© Copyright 2021 Optex Solar Pty Ltd. All rights strictly reserved.

Page 28

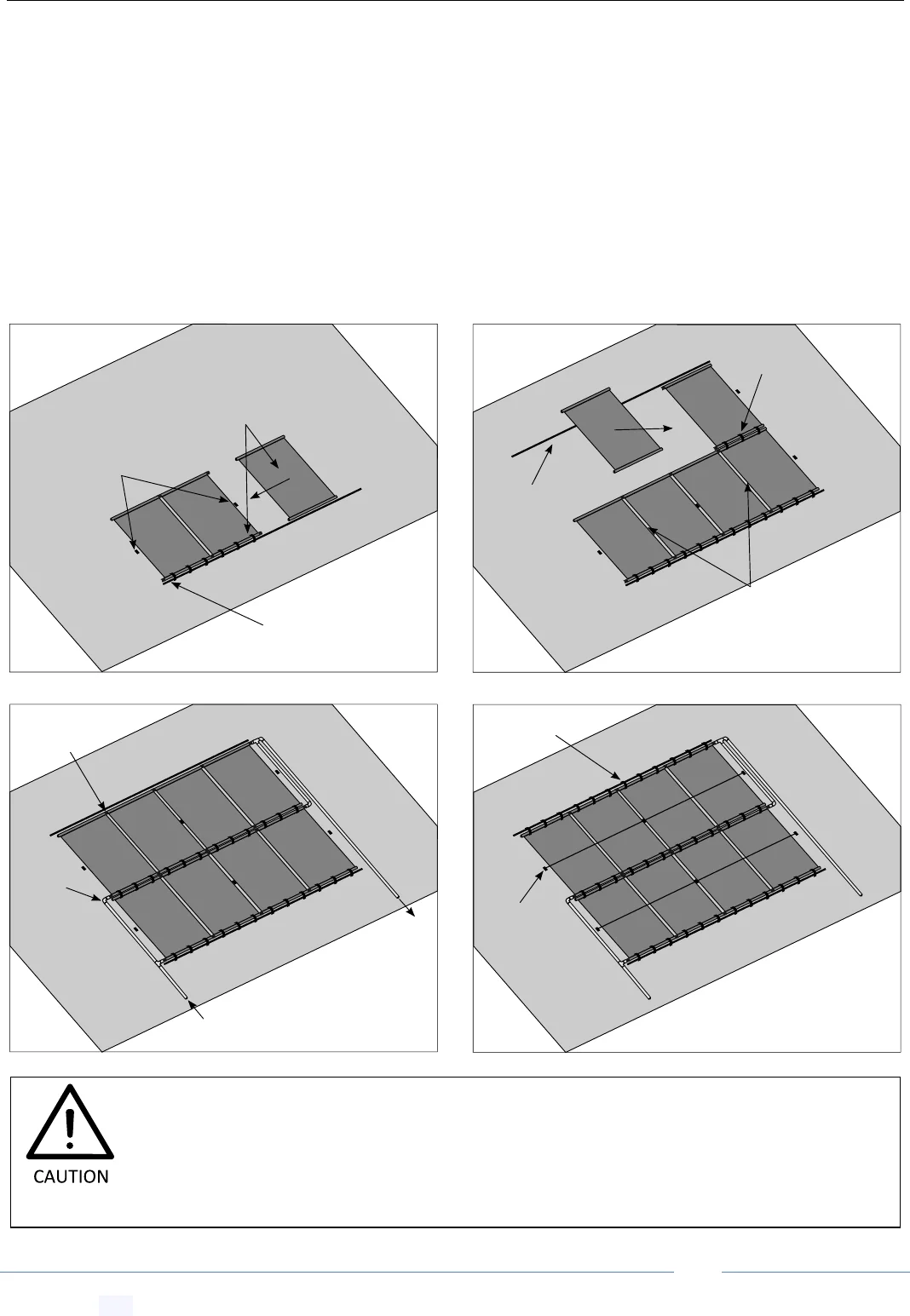

19.1 Single or Multi-Row Metal Roof Fixings Wind Region A

Create jump link to this section-- Get Link

For row arrays exceeding 15 panels per row, expansion joiners MUST be used (contact

info@EcoOnline.com.au)

EcoOnline Performance+™ Solar Pool Heating System -- Installation & User Manual

© Copyright 2021 Optex Solar Pty Ltd. All rights strictly reserved.

Page 29

19.2 Single or Multi-Row Metal Roof Fixings for Wind Regions B & C

Create jump link to this section-- Get Link

NOTE: For single or multi-row arrays in wind regions B or C, aluminium L-angle MUST be

installed for top and bottom of each row. Mid-panel attachments must also be installed.

For row arrays exceeding 15 panels per row, expansion joiners MUST be used (contact

info@EcoOnline.com.au)

EcoOnline Performance+™ Solar Pool Heating System -- Installation & User Manual

© Copyright 2021 Optex Solar Pty Ltd. All rights strictly reserved.

Page 30

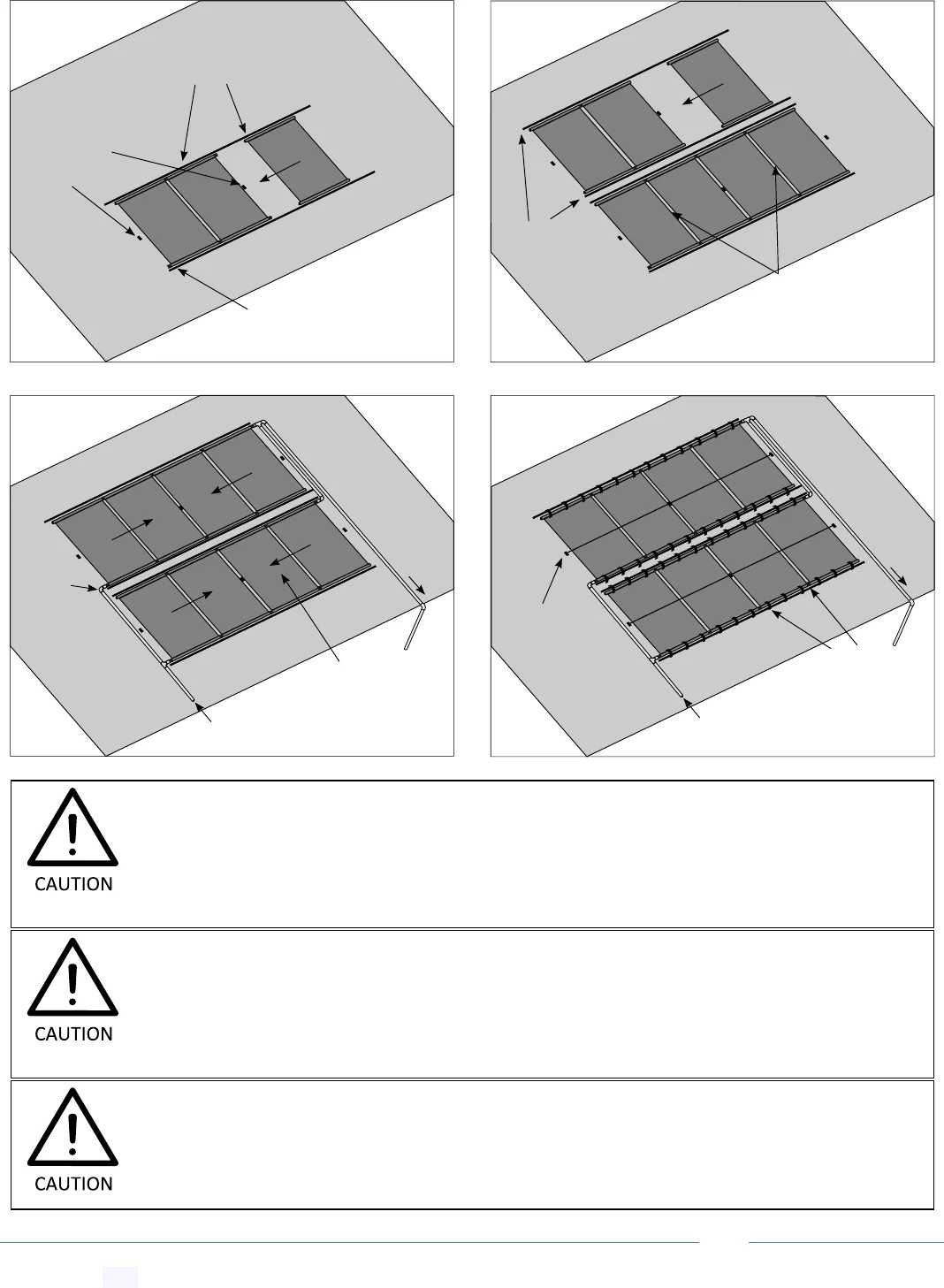

19.3 Single or Multi-Row Tile Roof Fixings for Wind Region A & B

Create jump link to this section-- Get Link

For single or multi-row arrays in wind regions B, aluminium L-angle MUST be run for the

top and bottom of each row.

For row arrays exceeding 15 panels per row, expansion joiners MUST be used (contact

info@EcoOnline.com.au)

EcoOnline Performance+™ Solar Pool Heating System -- Installation & User Manual

© Copyright 2021 Optex Solar Pty Ltd. All rights strictly reserved.

Page 31

19.4 Low Wind Area Alternate Two Row Roof Fixings

Create jump link to this section-- Get Link

Allowed for Region A, Terrain 3 Wind Loadings ONLY

Installation of two rows between two aluminium angles will require twice the expansion gap in

the stainless steel straps. We also highly recommend you “season” the panels before

installation to removed some of the permanent contraction the panels are prone to.

“Seasoning” the panels involves laying the panels out in the sun for half a day on one

side, then flipping over for the other side.

For dual row array fixed between top and bottom array aluminium channels, do not exceed

10 panels per row. If you need to have more than 10 panels we recommend each row have

aluminium railings. Why? Panels strapped top and bottom to an aluminium railing will have

smaller side to side thermal movements.

EcoOnline Performance+™ Solar Pool Heating System -- Installation & User Manual

© Copyright 2021 Optex Solar Pty Ltd. All rights strictly reserved.

Page 32

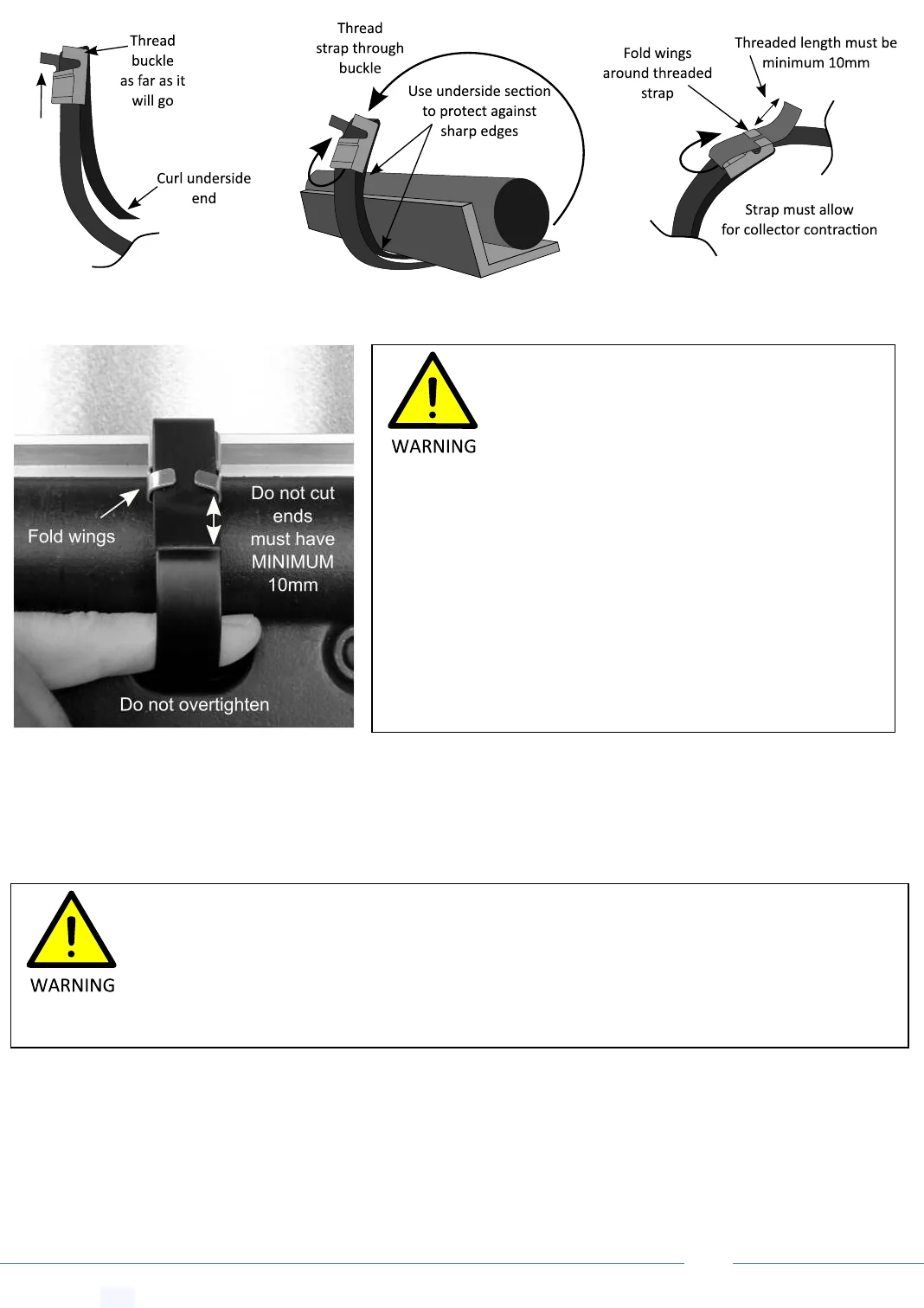

19.5 Application of the PVC Coated Stainless Steel Straps

Create jump link to this section-- Get Link

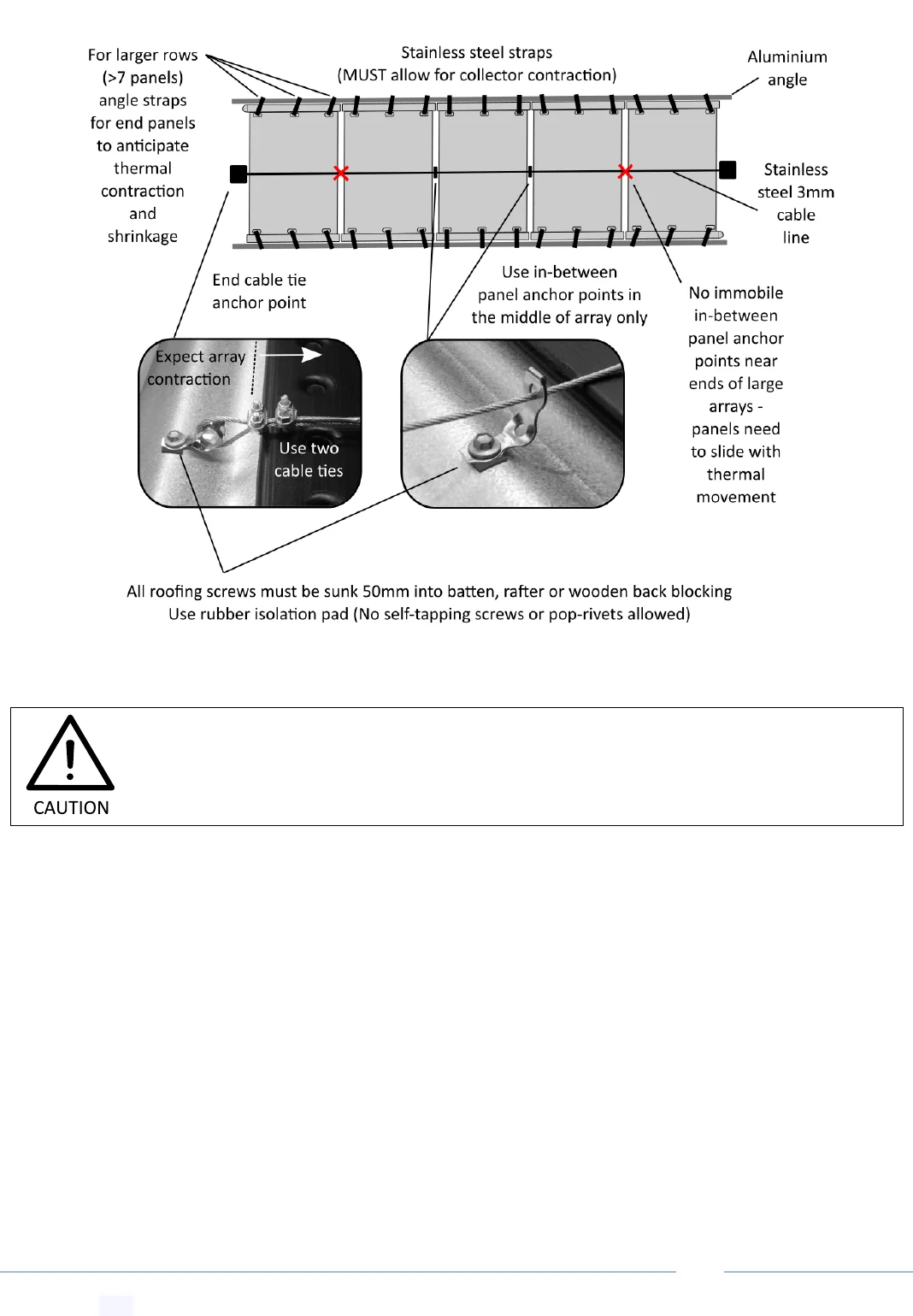

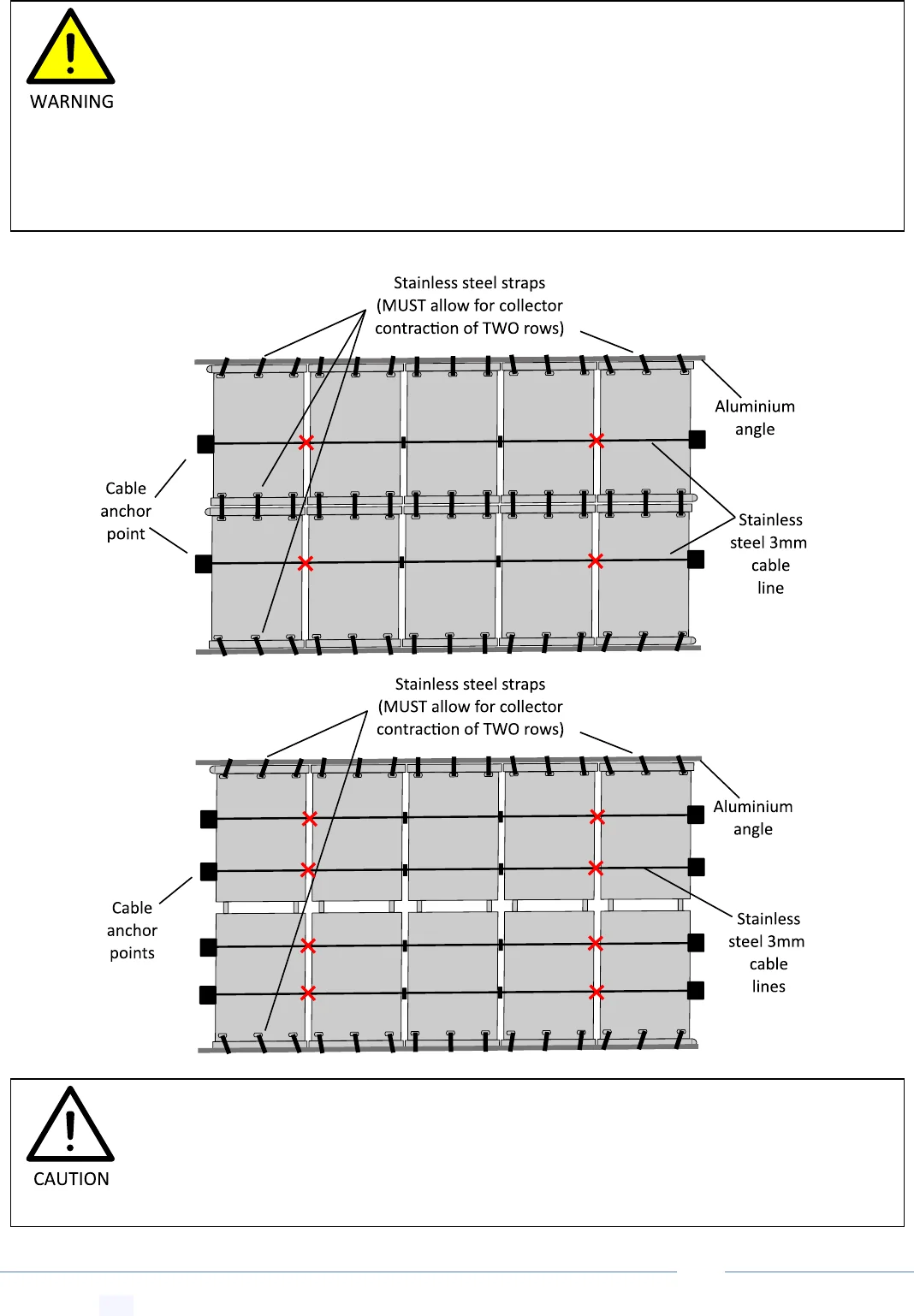

19.6 Three or More Row Roof Fixings

Create jump link to this section-- Get Link

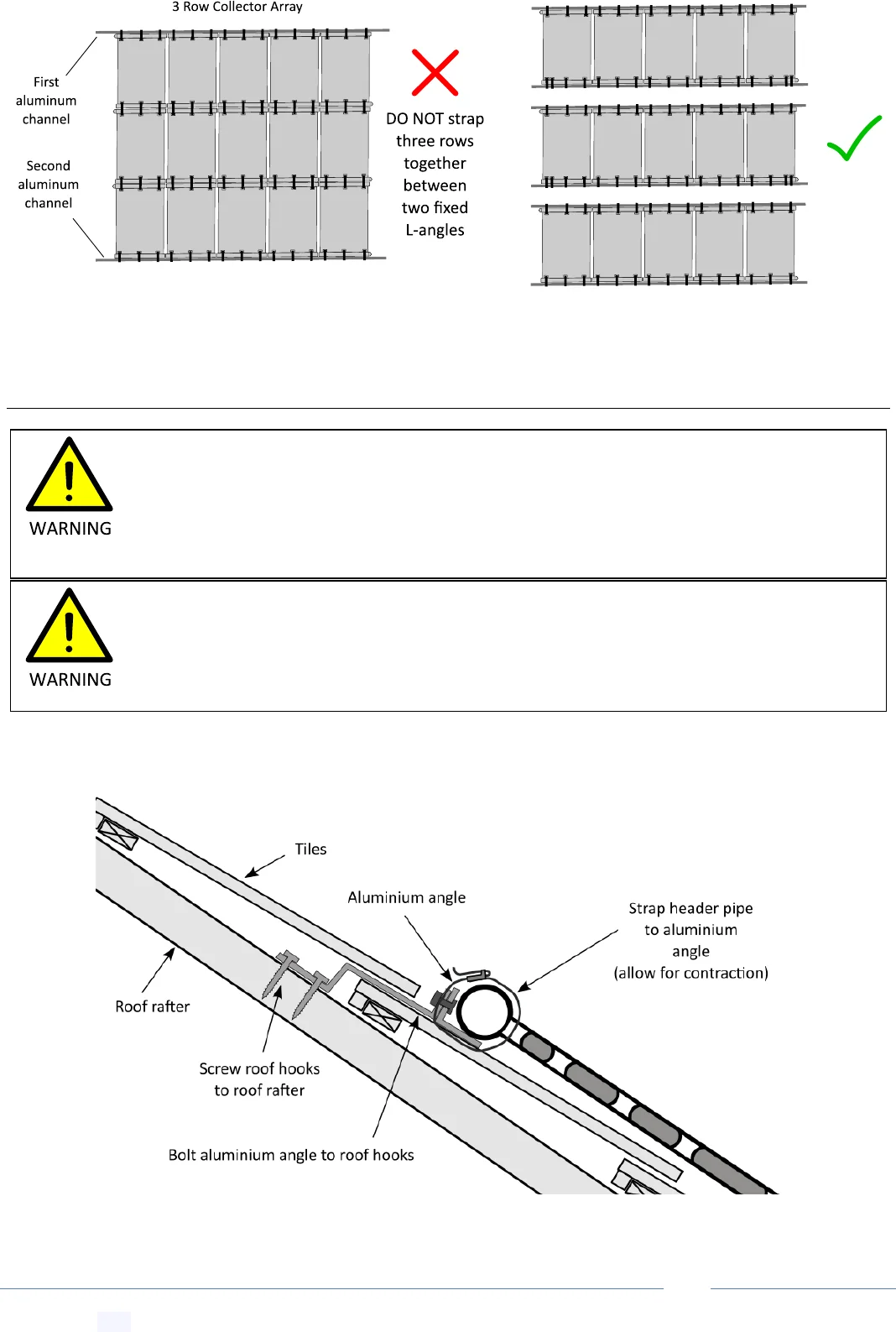

Due to the large potential thermal contraction across three rows the strapping of three

or more rows of panels between one set of fixed top and bottom aluminium angles is not

recommended. Collector arrays consisting of three or more rows must have a pair of

aluminium L-angles top and bottom for each row of collectors or at least for each pair of

rows to allow for contraction.

IMPORTANT: DO NOT over tighten stainless

steel strapping. Strapping must have sufficient

play to allow for collector contraction. For the

installation of two rows between two

aluminium channels top and bottom strapping

should be loose enough to insert your little

finger between the strapping and the header

pipe. Why? Over-tightened straps can

experience tension and continual flexing of the

metal due to the thermal contraction of the

collectors. This can result in metal fatigue of

roof fixings over time.

EcoOnline Performance+™ Solar Pool Heating System -- Installation & User Manual

© Copyright 2021 Optex Solar Pty Ltd. All rights strictly reserved.

Page 33

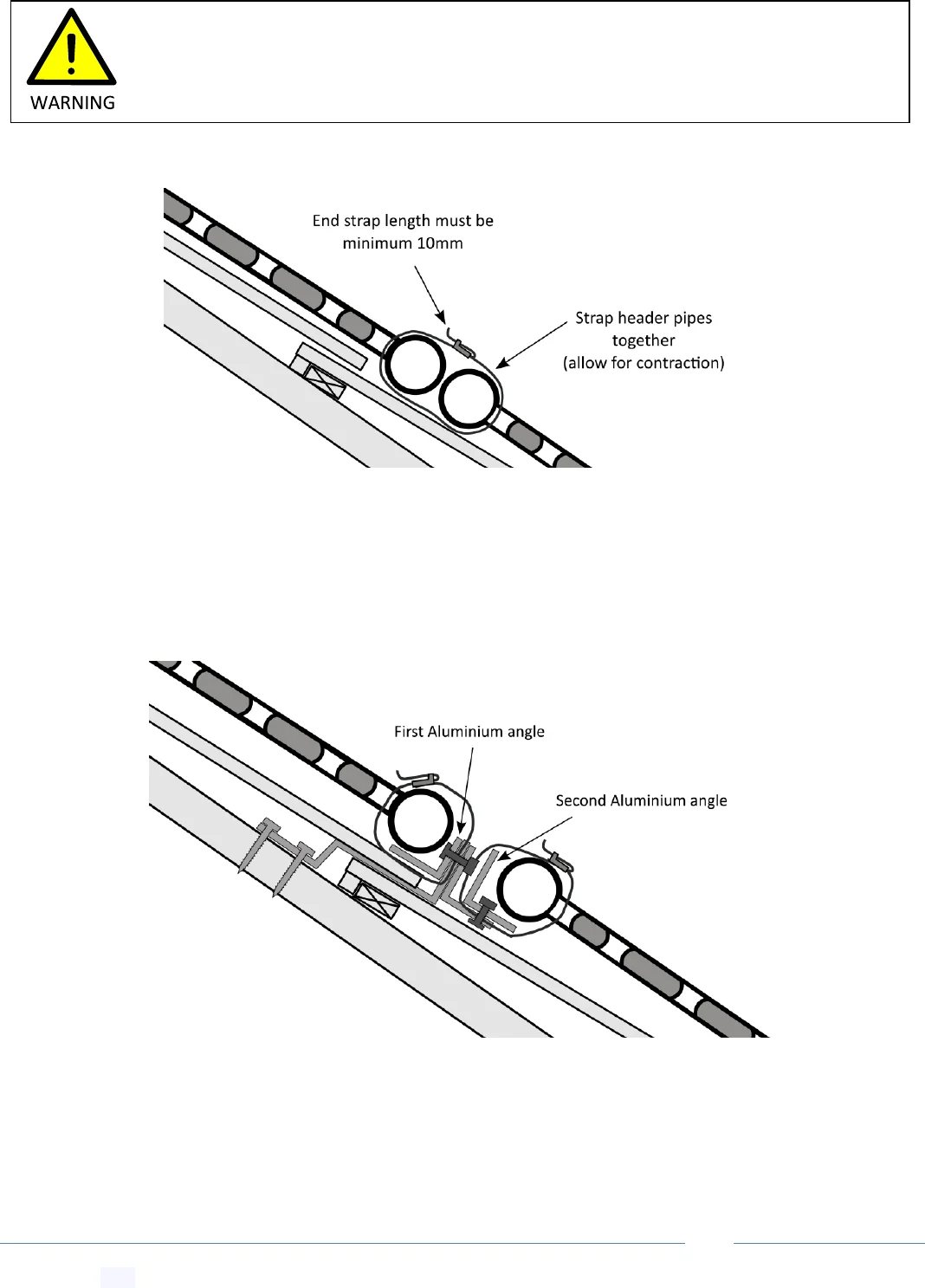

20 Tile Roof Aluminium Angle Mounting Options

Create jump link to this section-- Get Link

20.1 Top Panel Tile Attachment

Create jump link to this section-- Get Link

For tile roofs we recommend using a minimum roof hook spacing of 600mm in the top and

bottom row. Depending on your wind loading (see “Wind Proofing” section), angle of install

you may require a higher density of roof hooks and/or a stronger Aluminium L-angle, if unsure

please seek advice.

The collectors can be walked on without damage, however for tile roofs with solar roof hook

care should be taken not to step on or near a roof hook as you may crack a tile.

EcoOnline Performance+™ Solar Pool Heating System -- Installation & User Manual

© Copyright 2021 Optex Solar Pty Ltd. All rights strictly reserved.

Page 34

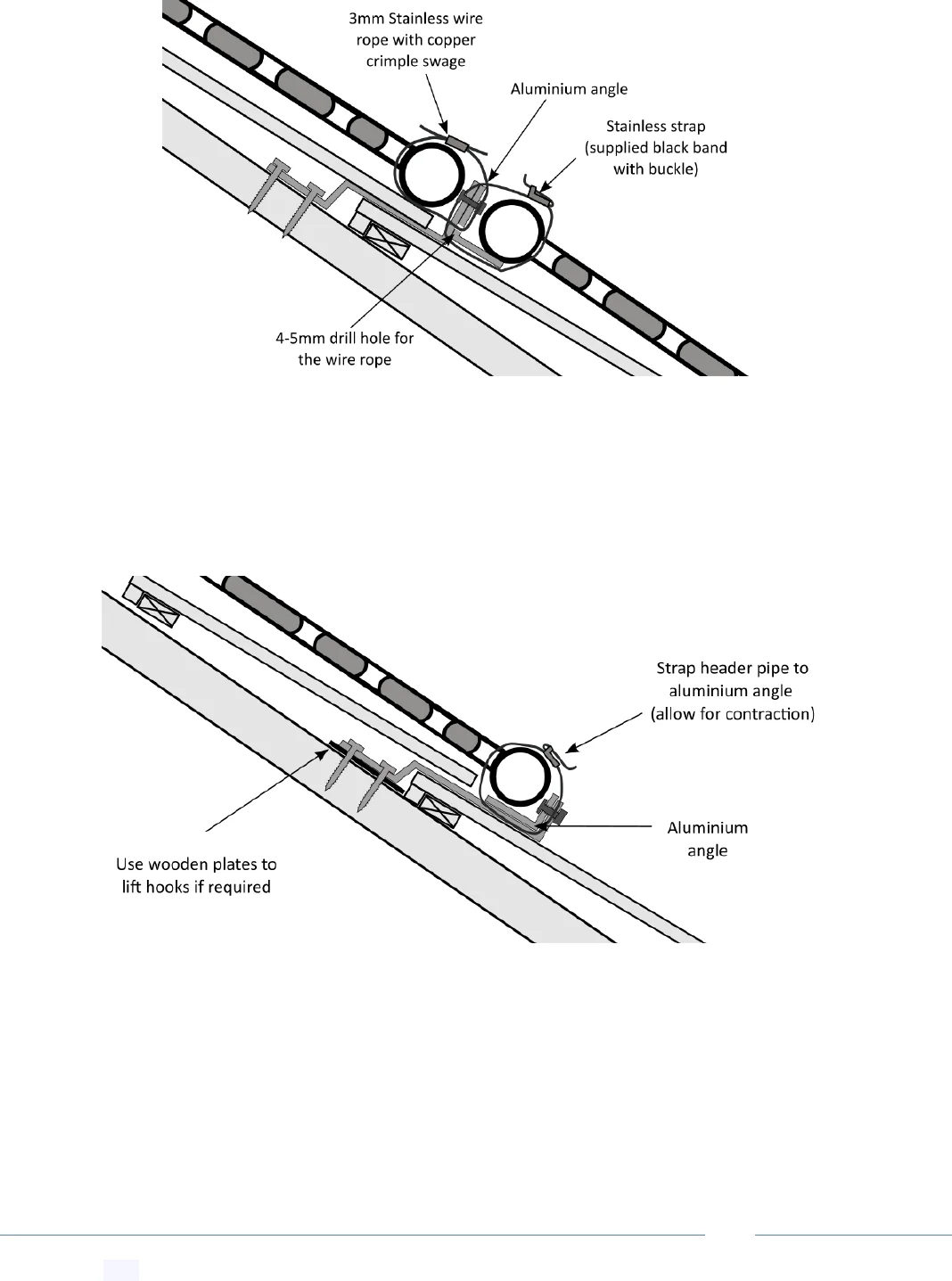

20.2 Two Row Panel to Panel Attachment

Create jump link to this section-- Get Link

20.3 Two Row Mid Array Panel Attachment – Dual Aluminium Angle

Create jump link to this section-- Get Link

Region A, Terrain 3 Wind Loadings ONLY

EcoOnline Performance+™ Solar Pool Heating System -- Installation & User Manual

© Copyright 2021 Optex Solar Pty Ltd. All rights strictly reserved.

Page 35

20.4 Two Row Mid Array Panel Attachment - Single Aluminium Angle

Create jump link to this section-- Get Link

20.5 Bottom Panel Tile Attachment

Create jump link to this section-- Get Link

EcoOnline Performance+™ Solar Pool Heating System -- Installation & User Manual

© Copyright 2021 Optex Solar Pty Ltd. All rights strictly reserved.

Page 36

20.6 Stainless Steel Cable Anchor Point Option

Create jump link to this section-- Get Link

20.7 Perforated Band Under-Tile Anchor Point

Create jump link to this section-- Get Link

EcoOnline Performance+™ Solar Pool Heating System -- Installation & User Manual

© Copyright 2021 Optex Solar Pty Ltd. All rights strictly reserved.

Page 37

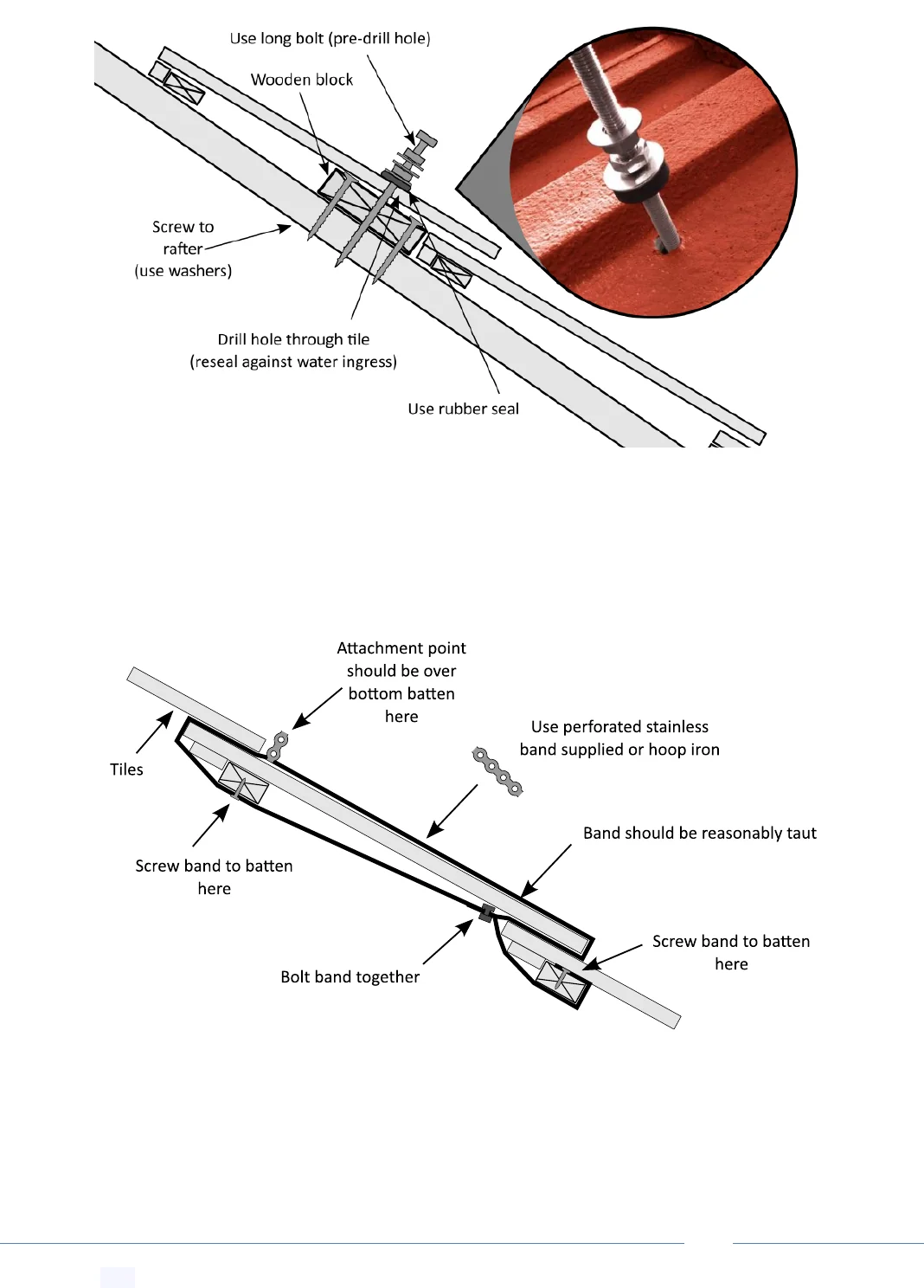

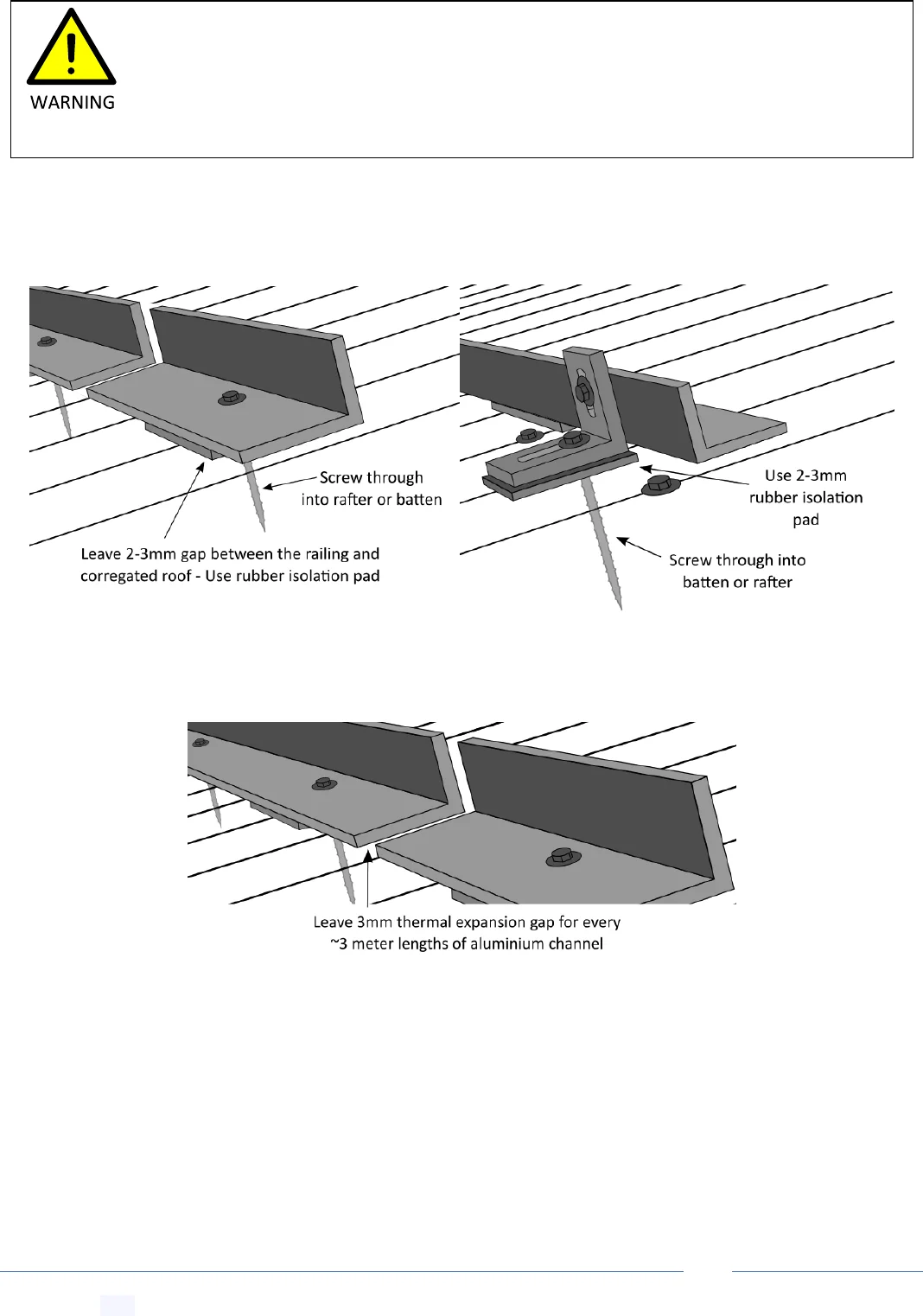

21 Corrugated Metal Roof Mounting Options

Create jump link to this section-- Get Link

21.1 Mounting Options for Top or Bottom Angle Rail

Create jump link to this section-- Get Link

21.2 Thermal Expansion Gaps for Aluminium Channels

Create jump link to this section-- Get Link

For metal roofs we recommend using a minimum screw fixing space of 600mm when fixing

the aluminium angle. Depending on your wind loading (see “Wind Proofing” section), angle of

install, you may require a higher density of fixings and/or a stronger Aluminium angle, if

unsure please seek advice.

EcoOnline Performance+™ Solar Pool Heating System -- Installation & User Manual

© Copyright 2021 Optex Solar Pty Ltd. All rights strictly reserved.

Page 38

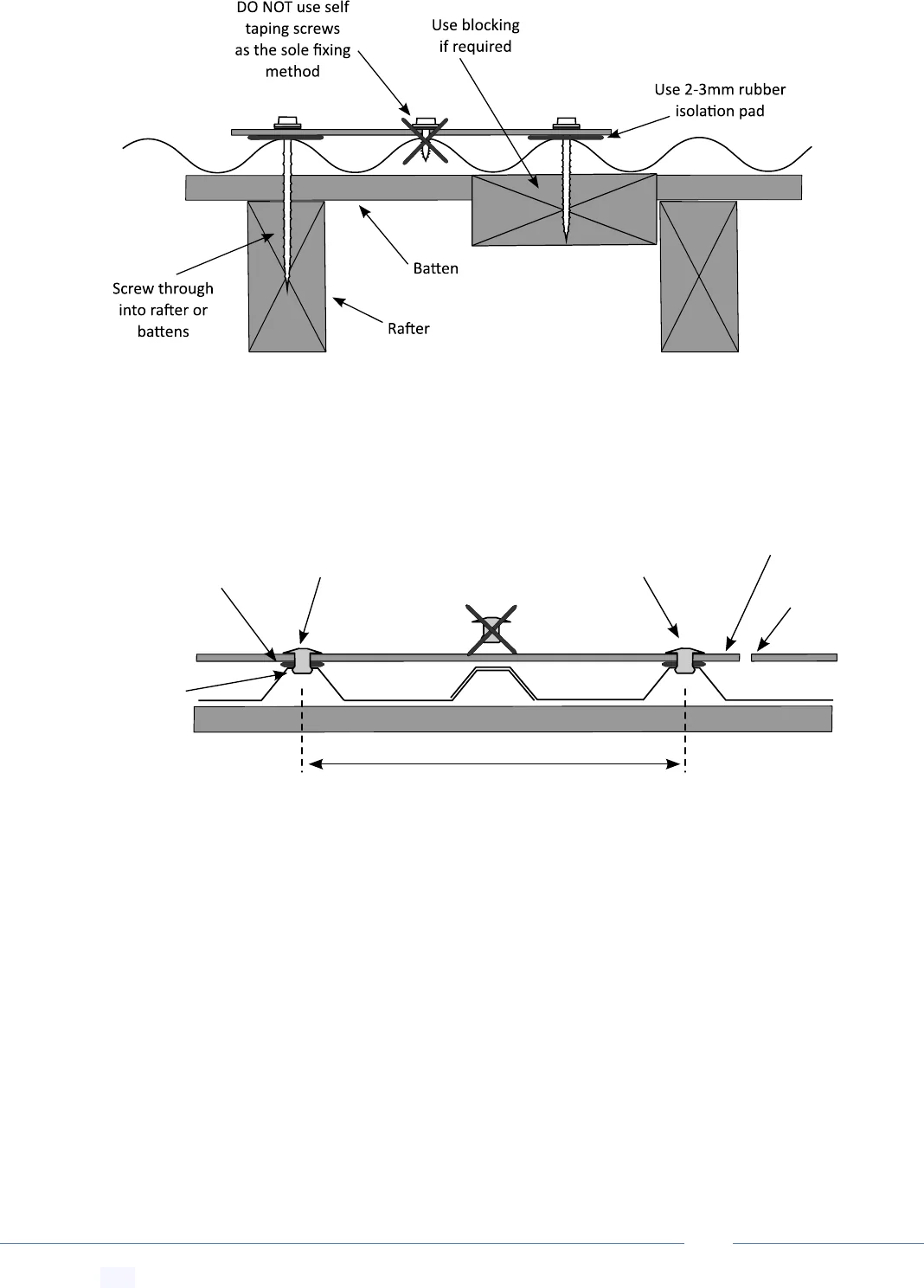

21.3 Metal Roof Screw Selection and Method

Create jump link to this section-- Get Link

21.4 Metal Roof Rivet Fixing Method for Wind Region A Only

Create jump link to this section-- Get Link

Use isolation pad

with silicon sealent

top and bottom

DO NOT rivet

overlap sections

Batten

Use 6.4mm body

diameter aluminium

rivets

Aluminium L-angle

(use max 2m lengths)

Leave 2-3mm

expansion gap

to next section

Space rivets ~250mm apart

Use silicon sealent

top and bottom

of rivet

After drilling hole

in roof profile wipe

silicon sealent on

the inside edge

(use hooked cotten bud)

EcoOnline Performance+™ Solar Pool Heating System -- Installation & User Manual

© Copyright 2021 Optex Solar Pty Ltd. All rights strictly reserved.

Page 39

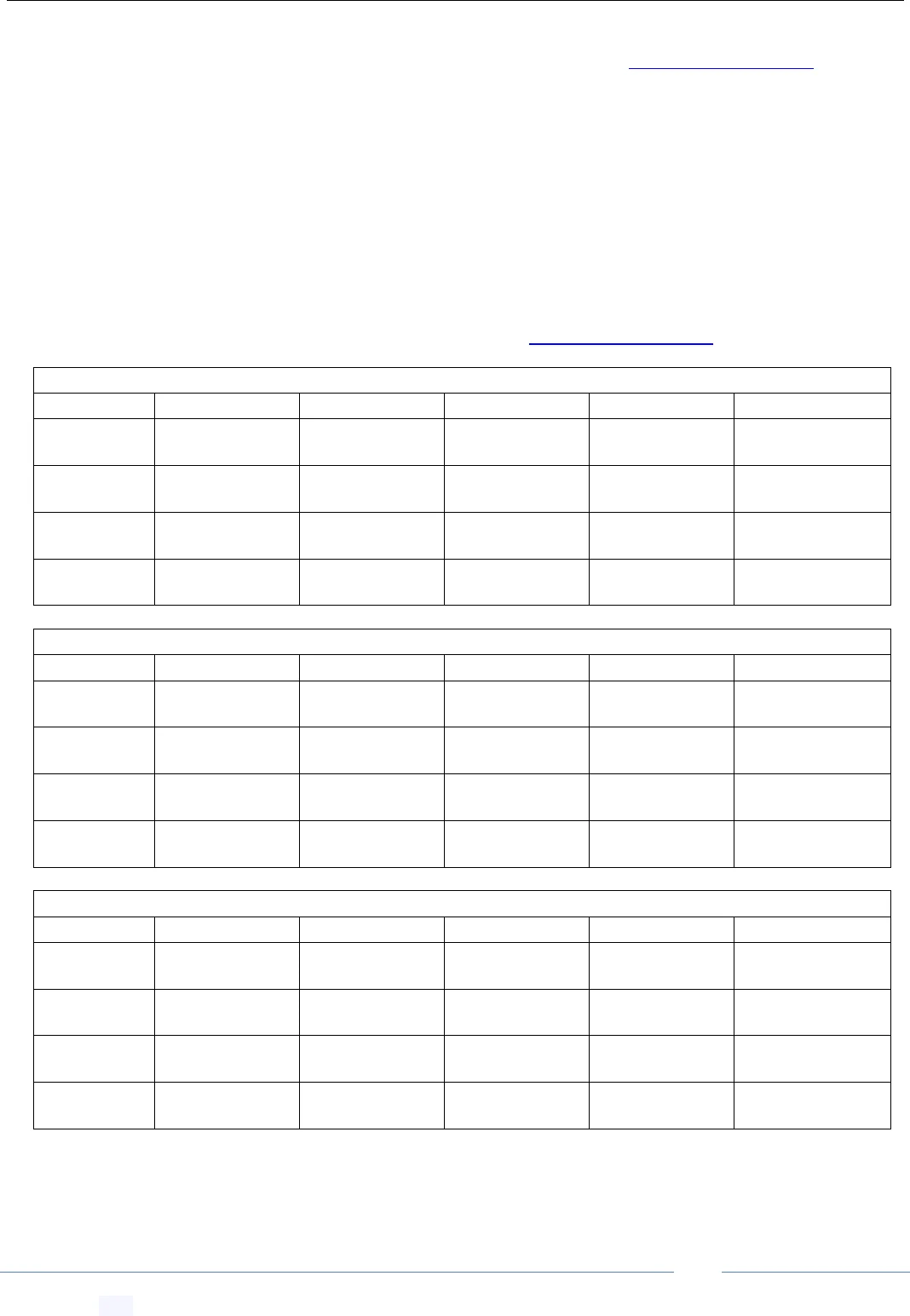

22 Wind Proofing

Create jump link to this section-- Get Link

Note: roof installation of these panels in Wind Region D is not recommended. This section provides general advice

on wind loadings. If you have any doubt about your wind loadings please contact info@EcoOnline.com.au

22.1 Ultimate Peak Wind Loadings per Panel

Create jump link to this section-- Get Link

The following Tables specify the ultimate peak uplift any single panel can experience in a 1 in 500 year extreme

storm or cyclone event according to Australian Standard 1170.2 - 2011 (Amend 2 Dec 2012). These tables assume:

1) Panels are mounted on (touching) the roof structure - or no more than 20mm off the roof surface

2) Panels are situated away from a roof edge or corner

3) Installation is on a first story roof

4) Shortest side length of the building is more than twice the average building height (i.e. flat building)

If your installation falls outside of these assumptions please contact info@EcoOnline.com.au for alternative loadings.

Ultimate Peak Uplift Loadings Per Panel in Wind Region A (Kg)

Region A

< 10˚ Roof Pitch

12.5˚ Roof Pitch

15˚ Roof Pitch

17.5˚ Roof Pitch

> 20˚ Roof Pitch

Terrain

Category 1

120 Kg

110 Kg

95 Kg

90 Kg

80 Kg

Terrain

Category 2

100 Kg

90 Kg

80 Kg

70 Kg

65 Kg

Terrain

Category 2.5

90 Kg

80 Kg

70 Kg

65 Kg

60 Kg

Terrain

Category 3

85 Kg

75 Kg

65 Kg

60 Kg

55 Kg

Ultimate Peak Uplift Loadings Per Panel in Wind Region B (Kg)

Region B

< 10˚ Roof Pitch

12.5˚ Roof Pitch

15˚ Roof Pitch

17.5˚ Roof Pitch

> 20˚ Roof Pitch

Terrain

Category 1

195 Kg

175 Kg

150 Kg

140 Kg

130 Kg

Terrain

Category 2

160 Kg

145 Kg

125 Kg

115 Kg

105 Kg

Terrain

Category 2.5

150 Kg

130 Kg

115 Kg

105 Kg

100 Kg

Terrain

Category 3

135 Kg

120 Kg

105 Kg

95 Kg

90 Kg

Ultimate Peak Uplift Loadings Per Panel in Wind Region C (Kg)

Region C

< 10˚ Roof Pitch

12.5˚ Roof Pitch

15˚ Roof Pitch

17.5˚ Roof Pitch

> 20˚ Roof Pitch

Terrain

Category 1

290 Kg

255 Kg

225 Kg

210 Kg

190 Kg

Terrain

Category 2

240 Kg

215 Kg

185 Kg

170 Kg

160 Kg

Terrain

Category 2.5

220 Kg

195 Kg

170 Kg

155 Kg

145 Kg

Terrain

Category 3

200 Kg

175 Kg

155 Kg

145 Kg

130 Kg

EcoOnline Performance+™ Solar Pool Heating System -- Installation & User Manual

© Copyright 2021 Optex Solar Pty Ltd. All rights strictly reserved.

Page 40

As an example if you are in Wind Region B and Terrain Category 3 and have a roof pitch 12.5˚ then any single panel

in your collector system could experience momentary peak uplifts of ~120Kg per panel. You should make sure your

panels and fixing components can withstand your relevant loadings. See below for Terrain Category definitions.

22.2 Terrain Category Definitions

Create jump link to this section-- Get Link

Terrain Category 1: Open terrain few obstructions. Example flat, treeless, poorly grassed plains.

Terrain Category 2: Open terrain with scattered obstructions having heights from 1 .5m to 5m, with at

least two building type obstructions per hectare. Example farmland and cleared subdivisions with

isolated trees.

Terrain Category 2.5: Averaged intermediate between Terrain Category 2 and Terrain Category 3

Terrain Category 3: Numerous closely spaced building obstructions having heights from 3m to 10m with

at least 10 house-size obstructions per hectare. For example a fully developed suburb or light industrial

estates.

22.3 Wind Region Definitions

Create jump link to this section-- Get Link

Coastal region boundaries are smooth lines set in from a smoothed coastline by 50km, 100km or 150km lines.

Note: Installations involving a second story roof or higher, or houses on hills, or panels

mounted 50mm or greater above the roof structure have higher potential wind loadings.

Please contact info@EcoOnline.com.au for ultimate wind loadings based on your details.

EcoOnline Performance+™ Solar Pool Heating System -- Installation & User Manual

© Copyright 2021 Optex Solar Pty Ltd. All rights strictly reserved.

Page 41

22.4 Frequency of Extra Fixings for Different Regions

Create jump link to this section-- Get Link

For ultimate wind loadings

(see Tables above):

Extra Fixings Required

Less than 70Kg per panel

Stainless guide line is not required (but still recommended)

Greater than 70Kg per panel

Stainless guide line is required across each row

Greater than 120kg per panel

Stainless guide line is required with in-between anchor points

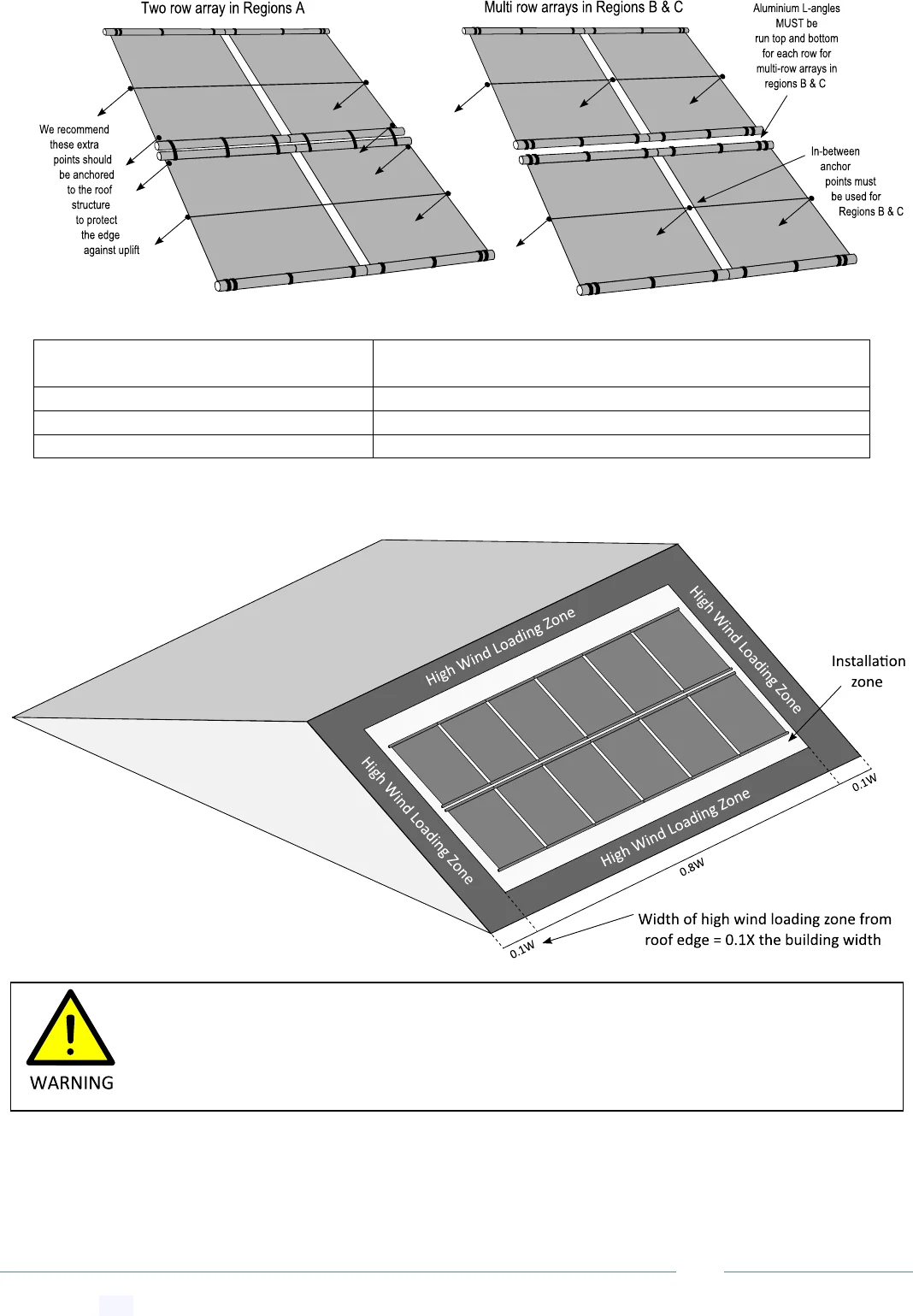

22.5 Roof Edge High Wind Loading Zones

Create jump link to this section-- Get Link

Note: Collector installations within a roof edge high wind loading zone will require 2 X the

fixing strength in that local area. Collector installations within a roof corner high wind loading

zone will require 3 X the fixing strength in that local area.

EcoOnline Performance+™ Solar Pool Heating System -- Installation & User Manual

© Copyright 2021 Optex Solar Pty Ltd. All rights strictly reserved.

Page 42

23 Seasoning Panels and Minimizing Contraction Issues

Create jump link to this section-- Get Link

Please be aware, collectors will naturally age and contract by up to 10mm in length (and proportionally in width)

per panel in the first 1-4 years. Collectors will also thermally contract on a daily basis from a hot panel (80˚) to a

cold panel (~0˚) by up to 12mm in length (and proportionally in width) per panel. No special care need be taken for

single row array with 6 or less panels in one row as the straps supplied can accommodate these thermal changes, for

other arrays please follow the below procedures.

23.1 Mounting Procedure for Arrays 10 or Less Panels per Row

Create jump link to this section-- Get Link

We recommend you “Season” the panels by placing them in the hot sun for half a day on one side and half a day on

the other side to minimize any age contraction issues later. Then follow this mounting procedure:

1 - Mount bottom rail

2 - Lay and bottom

strap collectors

3 - Measure

and mount

top rail

Do not use fixed

anchors on last few

end array panels due to

thermal movement

4 - Lay and strap second

row

5 - Lay

plumbing

and turn on

low pressure

flow to cool

and contract

collectors

6 - With water flow

tighten hose

clamps

8 - Install

any extra

windproofing

(if required)

7 - With water flow

install top

straps

Install windproofing

anchour points

(if required)

Apply and tighten hose clamps and fixing straps to cool panels only (and/or with cool water

running at low pressures, see Pressure Optimization section below) and never hot panels.

Why? Applying straps/clamps to hot panels can cause issues for large arrays when the

collector array contracts significantly in the cool of the night and over time.

EcoOnline Performance+™ Solar Pool Heating System -- Installation & User Manual

© Copyright 2021 Optex Solar Pty Ltd. All rights strictly reserved.

Page 43

23.2 Mounting Procedure for Arrays 15 or Less Panels per Row

Create jump link to this section-- Get Link

You MUST “Season” the panels by placing them in the hot sun for half a day on one side and half a day on the other

side to minimize any age contraction issues later. Then follow this mounting procedure:

1 - Mount aluminium rails

top and bottom of each row

4 - Mount

second top

rail set

6 - Lay

plumbing

and turn on

water flow to

cool and

contract

panels

7 - With low pressure

water flowing

compress rows as

much as possible

9 - Install

any extra

windproofing

(if required)

8 - With cool

water flowing

strap panels and

tighten hose clamps

3 - Connect panels

and apply hose clamps,

but do not strap them yet

5 - Continue

to lay second

row (if

required)

2 - Install wind

proofing anchor

points

(if required)

No saddle

PVC pipe

fixings

near

plumbing

joins

Do not use fixed

anchors on last few

end array panels due to

thermal movement

Compact panels pipe to pipe, tighten clamps and apply fixing straps to cool panels only

(and/or with cool water running at low pressures, see Pressure Optimization section below),

and never hot panels. Why? Applying straps/clamps to hot panels can cause issues for large

arrays when the collector array contracts significantly in the cool of the night and over time.

For arrays containing 11-15 panels in a single row we strongly recommend aluminium

channels top and bottom for each row. Why? Panels strapped top and bottom to an

aluminium railing will have smaller side to side thermal movements.

For these arrays we recommend you locate the vacuum release off the roof and run the

system at a slight negative pressure. Why? A slight negative pressure will help reduce side to

side thermal movement, help compact panels during installation and guard against pool drain

events caused by a joiner pulling out.

EcoOnline Performance+™ Solar Pool Heating System -- Installation & User Manual

© Copyright 2021 Optex Solar Pty Ltd. All rights strictly reserved.

Page 44

23.3 Mounting Arrays with 15 or More Panels per Row

Create jump link to this section-- Get Link

Please contact info@EcoOnline.com.au for special expansion joiners if you need to run your array with > (greater

than) 15 panels per row.

Arrays containing more than 16-20 panels in a row should only be installed with special

expansion couplings in the middle of the row to account for the thermal movement. Arrays

greater than 20 panels are allowed with extra expansion couplers; however a 100L/min flow

rate limitation per row applies.

EcoOnline Performance+™ Solar Pool Heating System -- Installation & User Manual

© Copyright 2021 Optex Solar Pty Ltd. All rights strictly reserved.

Page 45

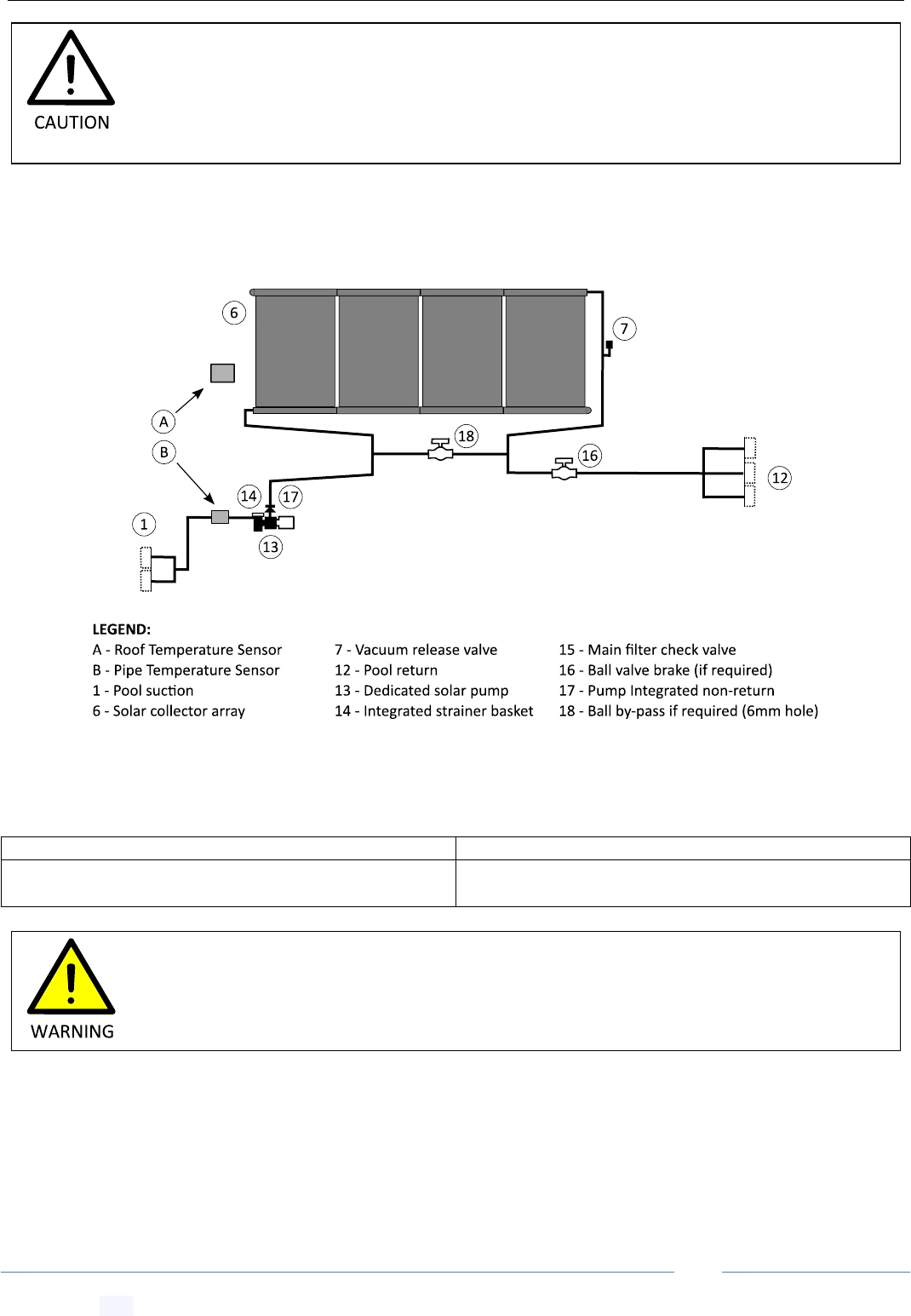

24 Plumbing Diagram Configurations

Create jump link to this section-- Get Link

24.1 Configuration 1: Independent/Separate System

Create jump link to this section-- Get Link

Notes: Solar pump can run independently of the filter pump. A and B are the recommended temperature sensor

installation zones for the controller

Advantages:

Disadvantages:

* More energy efficient as a small solar pump runs

independent of the large main filter pump

* Requires separate solar suction provisions to be

installed

When installing PVC lines, attention should be given to the minimum spacing for pipe

supports and thermal expansion of long length of pipe work and the stress this produces

on joins. For complicated installations we recommend a professional installer install the

system, unless you are confident of the work to be performed.

This system requires separate/independent Australian Standard approved suction and

return lines going into your pool. If you need to retro fit these you must contact a pool

builder.

EcoOnline Performance+™ Solar Pool Heating System -- Installation & User Manual

© Copyright 2021 Optex Solar Pty Ltd. All rights strictly reserved.

Page 46

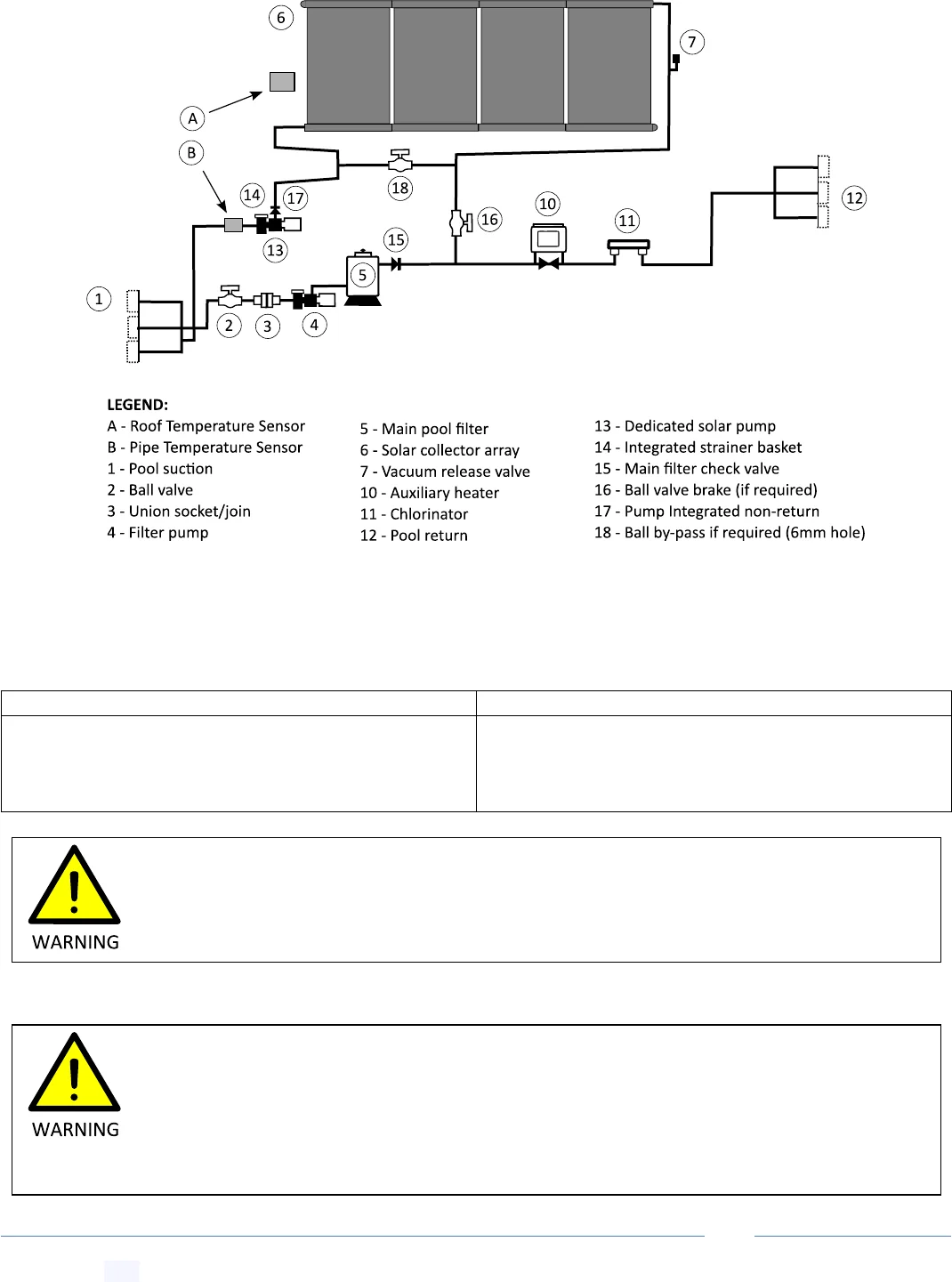

24.2 Configuration 2: Integrated Independent System

Create jump link to this section-- Get Link

Notes: For pool with only 1 return port, the filter pump must be set on a timer to run outside of solar hours to

exclude the possibility of the two pumps running together. A and B are the recommended temperature sensor

installation zones for the controller

Advantages:

Disadvantages:

* More energy efficient as a small solar pump runs

independent of the large main filter pump

* Can be retrofitted to older pools depending on access

to underground suction line

* Pumps can’t run simultaneously for pools with only 1

return port.

* Suction tees above or only just below the water line

will require regular maintenance of non-return valves

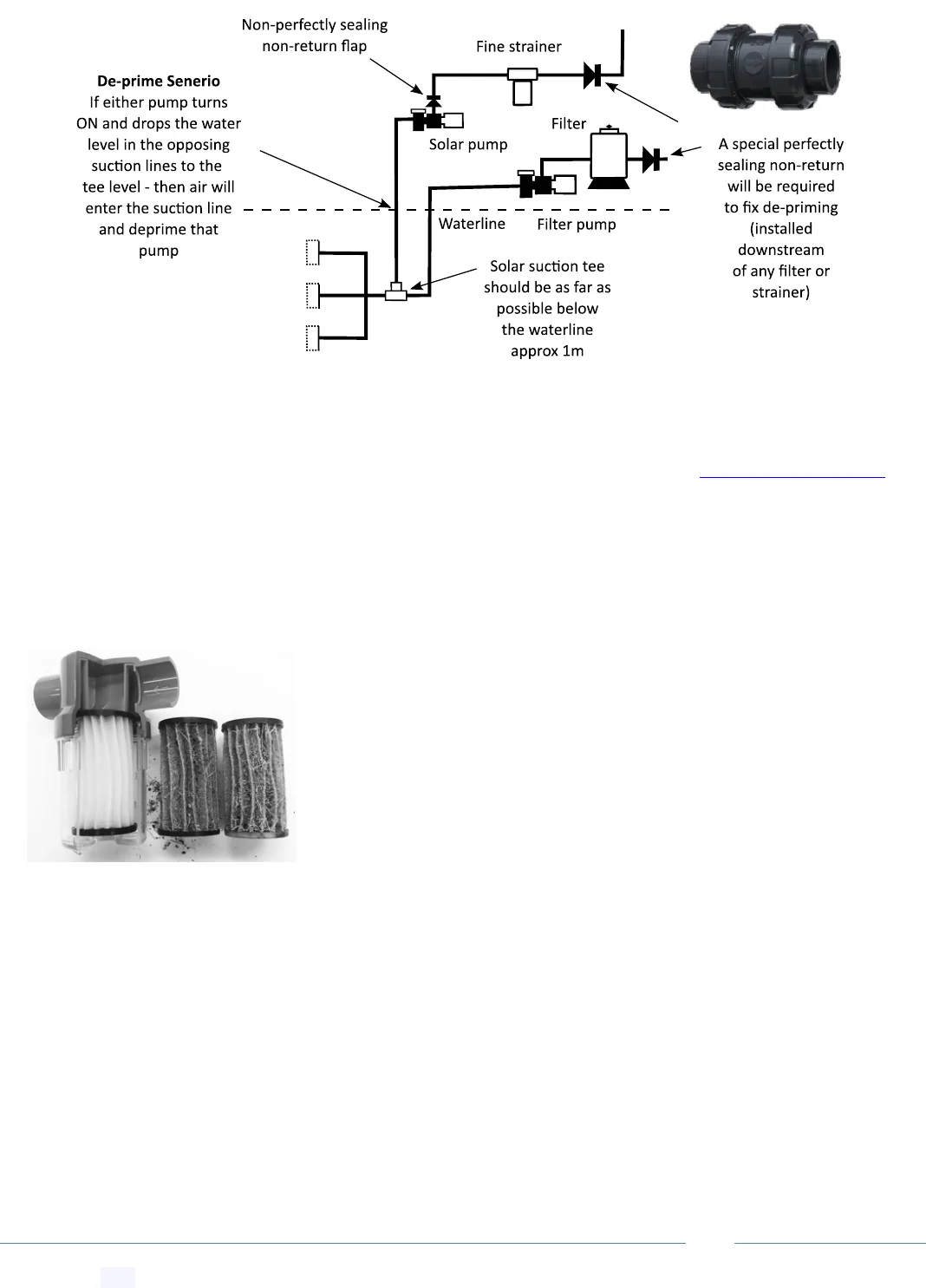

24.3 Notes on Teeing into the Suction Line for Configuration 2

Create jump link to this section-- Get Link

If the pool has more than one return port and the filter pump and solar pump run together,

the installer must check the combined flow does not exceed suction inlet flow rate limits.

checked.

Note: the tee into the suction line must be performed far below the waterline (> 1m).

Why? When the filter pump starts it will create negative pressure in the suction line which

will drop the water line in the solar suction line - if the water line drops below the tee point

air will be drawn de-priming the main filter pump.

EcoOnline Performance+™ Solar Pool Heating System -- Installation & User Manual

© Copyright 2021 Optex Solar Pty Ltd. All rights strictly reserved.

Page 47

If the tee can’t be installed more than 1m below the waterline, or if it can only be installed above the waterline,

some installers will put in a perfectly sealing non-return on the solar line to stop the main filter pump de-priming.

Please be aware, this is a special valve with a polished ball and rubber seat, contact us at info@ecoonline.com.au if

you require it. A standard flap non-return will not suffice. Also note, such a system will need regular careful

maintenance of the solar and filter line non-returns. Any failures or even the smallest leaks in these non-returns, due

to twigs or grit getting into the rubber seal, will pass air and eventually de-prime pumps.

24.4 Installing the Tuffman Fine Strainer

Create jump link to this section-- Get Link

The above scenario you will require the Tuffman fine to protect the non-

return from fine grit and twigs. Depending on the level of pool use and debris

in the pool the strainer may need to be cleaned regularly. Use a jet of water.

EcoOnline Performance+™ Solar Pool Heating System -- Installation & User Manual

© Copyright 2021 Optex Solar Pty Ltd. All rights strictly reserved.

Page 48

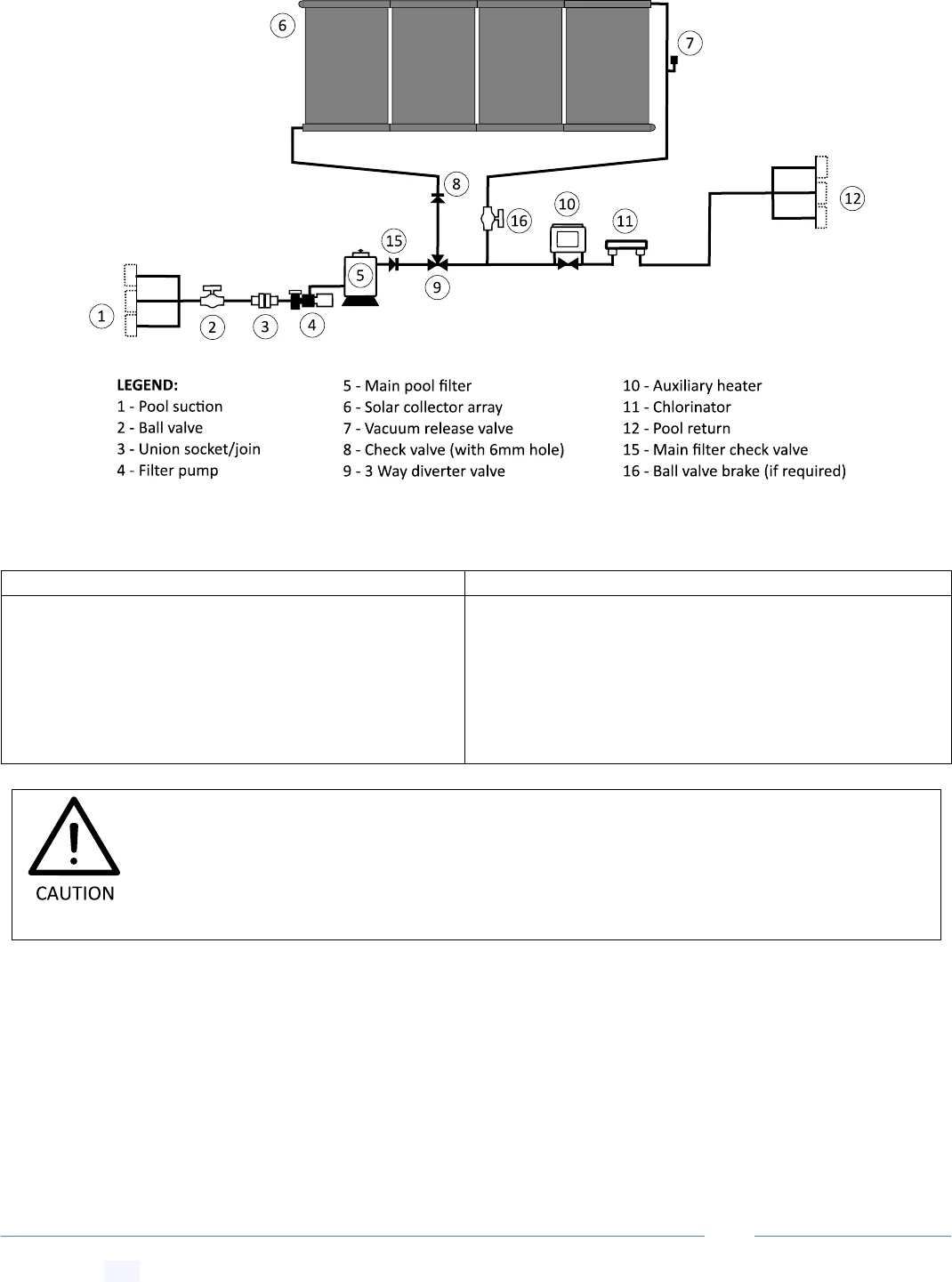

24.5 Configuration 3: Manual/Timer/Motorized Valve System

Create jump link to this section-- Get Link

Notes: Manual or motorized three-way valve (9). (Note: automatic controls are omitted for clarity).

Advantages:

Disadvantages:

* Manual system requires no extra pump required

* Manual system, needs to be turned off/on or on a timer

* Only filtered water runs through collectors

* Large main filter pump needs to run all day for solar

* Can be retrofitted to pools that don’t have separate

solar provisions

* Motorized three-way valve and controller can be

retrofitted later

* Requires specialized motorized valve and controller to

automate

* Increases pressure and decreases flow rate in the filter

system

* Not recommended for two story installations

For manual pool heating systems running off a main pool filter pump, please check that the

pump is large enough to accommodate the extra load of supplying water to the collectors

at the required pump height. Generally, this configuration is not recommended for two

story or greater installs.

EcoOnline Performance+™ Solar Pool Heating System -- Installation & User Manual

© Copyright 2021 Optex Solar Pty Ltd. All rights strictly reserved.

Page 49

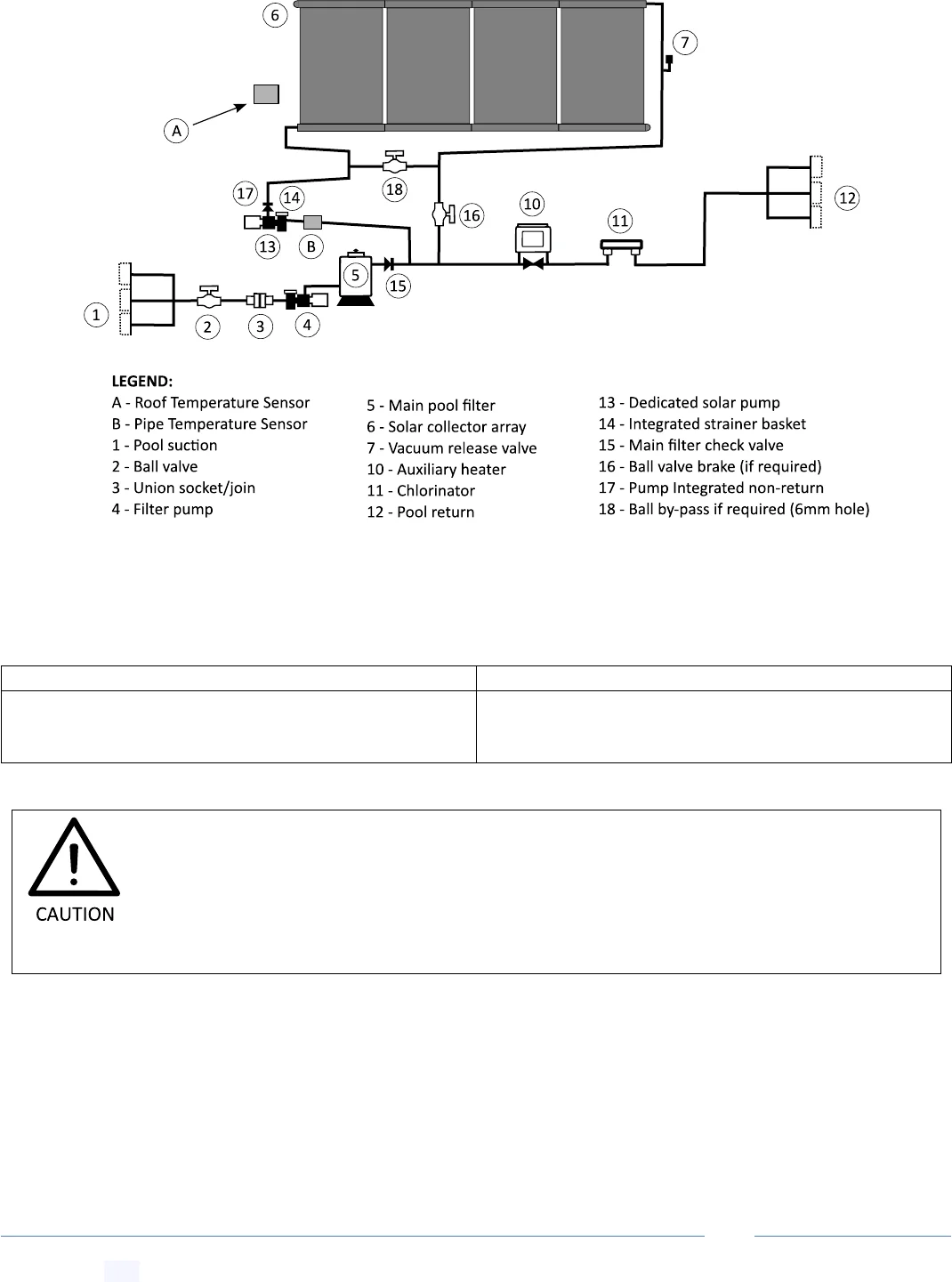

24.6 Configuration 4: Booster/Retrofit System

Create jump link to this section-- Get Link

Notes: Solar booster pump locked to run with filter pump - requires specific controller Dontek V7RTS. Solar pump

(13) should of lower flow than filter pump (4). A and B are the recommended temperature sensor installation zones

for the controller

Advantages:

Disadvantages:

* Less extra plumbing is required for solar

* Requires second pump and special controller

* Only filtered water runs through collectors

* Does not require separate solar suction provisions

* Large main filter pump + solar pump need to run all

day for solar

This configuration is not recommended for single story installs for pools with only a single

return port due to the potential over pressurization of the panels when both pumps run at

the same time. However for two story or greater installs, even with a single return port, this

is the recommended configuration for pools that don’t have separate suction ports.

EcoOnline Performance+™ Solar Pool Heating System -- Installation & User Manual

© Copyright 2021 Optex Solar Pty Ltd. All rights strictly reserved.

Page 50

25 Installing the Controller for Independent Systems

Create jump link to this section-- Get Link

Please refer to the controller manual as different controllers have specific installation instructions. Here we only add

supplemental instructions; they should not override any specific controller instructions. Note: controller manuals are

downloadable from the EcoOnline website.

25.1 Installing the Roof/Hot Sensor

Create jump link to this section-- Get Link

If your controller comes with a long 20m cord hot roof sensor it should be adhered using silicon to a sun exposed

roof tile or section of corrugated metal roof. It should NOT be installed, on top off, inserted into, or under an OKU

panel. Ideal placement is within arm’s length of the gutter.

25.2 Installing the Pool/Cold Sensor

Create jump link to this section-- Get Link

The cold sensor should be fitted inside a section of PVC suction line (before the solar pump) and sealed using the

grommet supplied. For this you will need to drill a hole in the suction line, please check the controller manual for the

recommended size.

25.3 Extending Sensor Cords

Create jump link to this section-- Get Link

The sensor cords can be extended using a similar type cord but in a larger gauge wire. Note, the Dontek cold sensor

uses a shielded type cord; hence you will need the same (but in a higher gauge) if extending it. Please contact

Dontek or Ascon if unsure.

When extending the cord we recommend a “lap splice” solder join with adhesive heat shrink.

Solder joins should not placed in any conduit section running under ground.

If the cord is too short the sensor can also be located on any unshaded “roof proxy”

surface that faces the same part of the sky as the panels to approximate the surface

temperature of the roof itself. Alternatively, it can be extended see below.

Standard unmodified drill bits have “positive rakes” and can easily “bite into” soft

materials. This can cause a sprain injury as a hand drill will violently kick and spin. Drill bits

can easily be modified to “zero rake” to prevents this, see

https://www.youtube.com/watch?v=pAngKHIZgyA. Alternately, a step drill bit or a

standard drill bit spun backwards can be used. A cone shaped rolled up piece of sandpaper

can be used to even out or increase the diameter of the hole to size.

PVC plastic should be preheated to 50˚C using a heat gun to prevent it from splitting

during drilling. We recommend you practice on a pipe off cut before attempting the

hole.

EcoOnline Performance+™ Solar Pool Heating System -- Installation & User Manual

© Copyright 2021 Optex Solar Pty Ltd. All rights strictly reserved.

Page 51

26 Drain-Down, Frost Proofing and Winterization

Create jump link to this section-- Get Link

26.1 Drain Down

Create jump link to this section-- Get Link

All pool heating systems have a drain down design and MUST drain as fully as possible when the system stops.

26.2 Winterization

Create jump link to this section-- Get Link

Please note, while your potable HPDE/Silicon collector array does not require regular winter flushing, your solar

booster pump may require winter flushing. If this is the case and you do not want to run your system over winter

you can winterize your system by draining the solar side of the system, disconnecting the solar booster pump and

flushing the pump with clean water for storage over winter.

26.3 Installing a By-Pass Tube or By-Pass Ball Valve (18)

Create jump link to this section-- Get Link

A drain tube (or a by-pass ball valve with 6mm hole) can be used to drain non-self draining sections of PVC piping in

frost prone areas. In some cases where there are issues with pump priming and a perfectly sealing non-return valve

(8) is required; the aforementioned by-pass lines can be installed on the supply and return solar lines leading up to

the roof approximately one metre above pump level to reduce priming pressure. Please request this component if

you require it.

To install, drill into the PVC pipe using a modified “zero rake” 8.5mm drill bit. Insert the

rubber grommet into the hole first, and then insert the single barb side barb into the

grommet. Finally connect the by-pass tube to the double barb side barb ends.

The use of a water tight non-return valve on the solar supply will prevent drain down

which could result in water freezing inside PVC piping in frost prone areas and/or hot

water stagnation in summer. Any non-return valves installed on the supply line MUST

have a 6mm drain hole drilled in the flap to allow drain down. Why? The main purpose

of the non-return valve is to prevent a large volume of water from spinning the pumps

rotor backwards when the pump stops. A 6mm hole allows slow drain down while also

preventing hammer action in the flap when the pump stops.

PVC piping should be installed with a slope such that all water drains out of the piping to

when the pump stops to ensure a freeze proof system. There should be no U-bend water

traps - these can freeze over and burst plumbing lines in the winter. Note: PE lines are not

affected as these are frost impervious.

Independent systems with a drain tube anywhere in the

system MUST be installed with a fine (<0.5mm) strainer,

or else this tube may get blocked up.

EcoOnline Performance+™ Solar Pool Heating System -- Installation & User Manual

© Copyright 2021 Optex Solar Pty Ltd. All rights strictly reserved.

Page 52

27 Optimizing Collector Pressure

Create jump link to this section-- Get Link

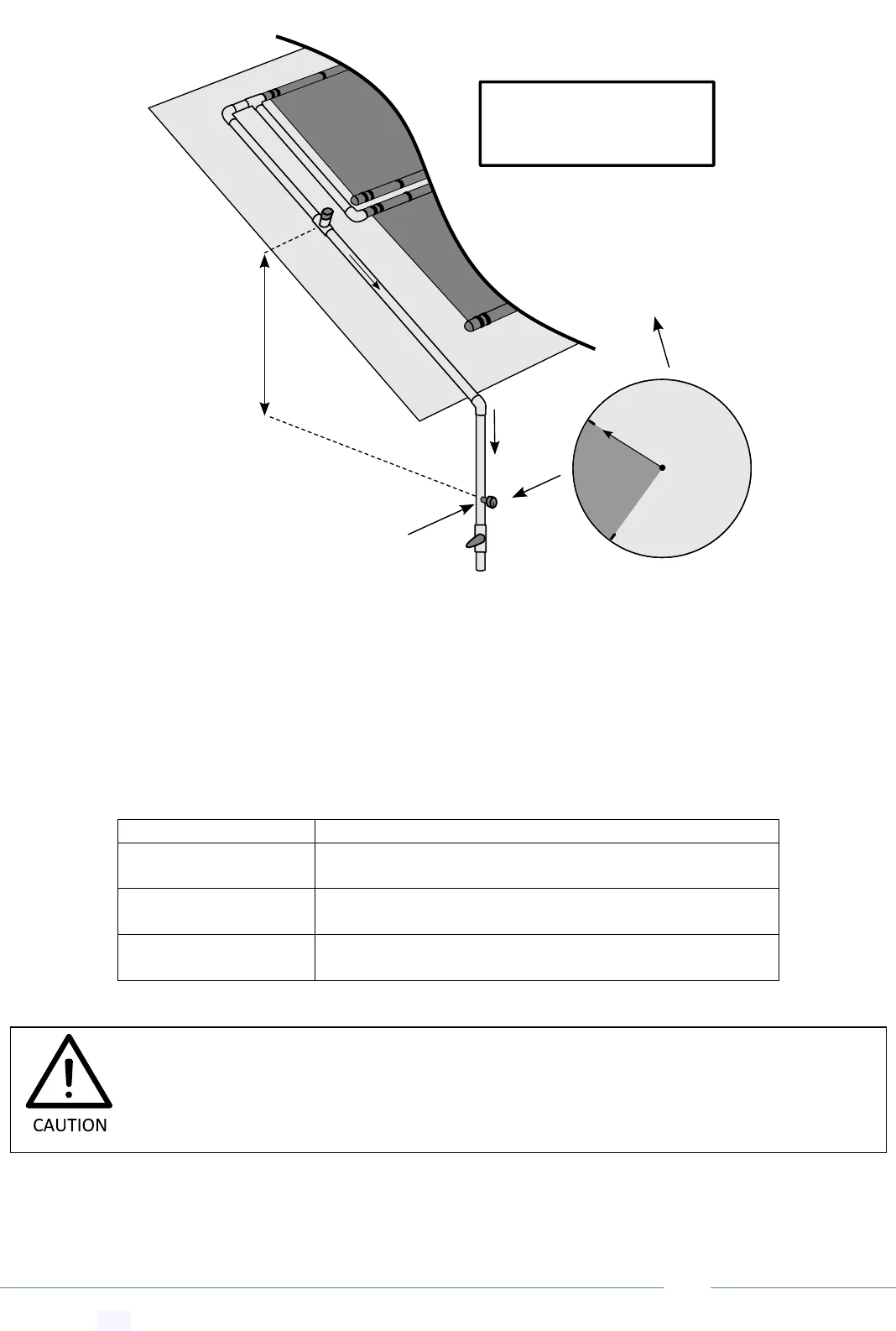

27.1 Installing the Pressure Gauge

Create jump link to this section-- Get Link

The pressure gauge must be installed on the return line preferably near eye level. Drill

into the PVC pipe using an 8.5mm drill. Insert the rubber grommet into the hole

tapered end first. Use pink Teflon tape on brass tread, lubricate the brass barb with

silicon spray prior to insertion into the grommet. Note: PVC plastic should be

preheated to 50˚C using a heat gun or it may split when drilling.

27.2 Zero Pressure Panel Check Procedure

Create jump link to this section-- Get Link

To make pressure adjustment depending on over-pressure or under-pressure situations, you’ll need to install either

a ball by-pass valve (18) to reduce pressure or a ball break valve (16) on the return line to increase back pressure

(both at near ground level for easy adjustment). Manual type systems need only the adjustable 3-way ball valve.

Collector pressures can then be adjusted as follow:

Standard unmodified drill bits have “positive rakes” and can easily “bite into” soft

materials. This can cause a sprain injury as a hand drill will violently kick and spin. Drill bits

can easily be modified to “zero rake” to prevents this, see

https://www.youtube.com/watch?v=pAngKHIZgyA. Alternately, a step drill bit or a

standard drill bit spun backwards can be used. A cone shaped rolled up piece of sandpaper

can be used to even out or increase the diameter of the hole to size.

PVC plastic should be preheated to 50˚C using a heat gun to prevent it from splitting

during drilling. We recommend you practice on a pipe off cut before attempting the

hole.

EcoOnline Performance+™ Solar Pool Heating System -- Installation & User Manual

© Copyright 2021 Optex Solar Pty Ltd. All rights strictly reserved.

Page 53

Gauge Pressure

Pressure Adjustment Advice

Less than:

Head Pressure - 2 kPa

Install ball valve brake (16) (see plumbing diagrams) to

increase back pressure in return line

Up to:

Head Pressure + 4 kPa

Pressure is okay no action required

Greater than:

head Pressure + 4 kPa

Excessive pressure - install extra pool returns or remove

eyeballs from returns, or install by-pass (19) with ball valve

Head Pressure :

Vertical measure

from vacuum

release to

pressure gauge

Note:

1m vertical Head Pressure = 10 kPa

2m vertical Head Pressure = 20 kPa

To

pool

Pressure gauge is mounted

above the break ball valve

0 kPa

23 kPa

head

pressure

2.3m

example

pressure

gauge

reading

For an example 2.3m vertical

distance between the vacuum

release and the pressure

gauge, the gauge

should read:

~ 23 kPa

Ideal pressure gauge reading

=

Head Pressure

It’s important OKU panels are run at near zero pressure up on the roof, however pressure ±

4kPa are also acceptable. Larger pressure may limit collector lifetimes.

Why? Plastic longevity is strongly dependent on pressure fluctuations and temperatures.

EcoOnline Performance+™ Solar Pool Heating System -- Installation & User Manual

© Copyright 2021 Optex Solar Pty Ltd. All rights strictly reserved.

Page 54

27.3 Negative Pressure and Air Bubble Issues

Create jump link to this section-- Get Link

If the pump height is substantial and/or you have more than one return outlet to your pool, it may be that your

pump cannot positive pressurize the vacuum release valve. In this case you will get undesirable constant bubbling in

the outlet to the pool as the vacuum release valve is at negative pressure and is drawing in air. If this happens you

will need to install the down draft/brake PVC ball valve (16) on the return line (see plumbing diagrams) and carry out

the following procedure:

Start the system and wait for it to settle.

1) Constrict flow in the return line using the ball valve brake (16, see plumbing diagrams) lever handle by a

small increment.

2) If after some time the air bubbling continues, constrict flow by another small increment.

3) If air bubbles stop reliably at this point then the vacuum valve is now at the required positive pressure, the

pressure gauge should read a value near the head pressure (vertical distance from vacuum release and

pressure gauge) + a few kPa’s, this is ideal.

4) Leave the ball valve brake at this setting/constriction permanently (remove handle).

5) If the required constriction is greater than 50% you will need a stronger pump.

27.4 Adjusting the 3 Way Valve for Manual Systems

Create jump link to this section-- Get Link

The following procedure for a manual system need be carried out only once during installation.

1) Open the three way ball valve (9, see plumbing diagrams) using the lever handle by a small increment.

2) Wait to see if there is sufficient flow and back pressure to create positive pressure at the vacuum valve (7).

3) If after some time air bubbling is still present in the return line, open the three way valve (9 see plumbing

diagrams) by another small increment.

4) If air bubbles stop reliably at this point then the vacuum valve is now at the required positive pressure.

5) Fix in place a back stop on the ball valve lever handle at this travel point, as this will be your maximum

opening point for your three way valve when turning the heating system on again.

Never expose the collector array to temporary pressures greater than 16 psi (110kPa).